Researchers from the University of New South Wales have created vortex generators that can reportedly reduce the operating temperature of the solar module by up to 2.5C. They built two different prototypes, based on aluminum and a conductive 3D-printable polymer, and tested them under different scenarios in an experimental laboratory. institution deployed in Sydney.

Scientists from the University of New South Wales (UNSW) in Australia have used rectangular vortex generators (VGs) as a passive cooling technique for photovoltaic panels and found that they can reduce the operating temperature of the modules by 1.5 to 2.5 C.

VGs are often used to slow the separation of flows and are often placed on the outer surfaces of vehicles and wind turbine blades. These devices have also been applied at research level for cooling in photovoltaic-thermal (PVT) modules, but have not yet been used only for PV modules due to “completely unpredictable” flow conditions, according to the research team.

“Our previous indoor experiments have shown that the rectangular wing can cool VG by up to 3 degrees Celsius under free convective conditions,” the scientists explained, referring to an earlier attempt they made to use VGs for cooling PV panels. “By introducing longitudinal vortices close to the rear surface of the module, a series of VGs enhance convective heat flow, reducing the module operating temperature. In this study, the same VG design was applied to an outdoor installation with an open rack PV system.”

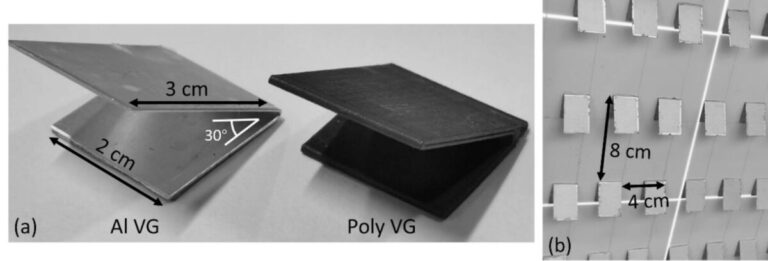

The scientists used VGs measuring 2 cm x 3 cm and with a rectangular wing shape bent at a 30 degree angle. They built 400 pieces based on aluminum and 400 pieces based on a conductive 3D-printable polymer. They were then attached to the back of two different 285W polycrystalline panels supplied by the Taiwanese manufacturer Winaico. The academics also used thermally conductive tape to create thermal contact between the VG and the module.

“Except for the bottom and top rows of silicon cells, where the junction box is located, the VGs occupied most of the 1m x 1.65m module area,” they explained. “The vertical pitch is 8 cm, allowing two rows of VGs to be installed on one M2 size cell and sixteen rows of VGs on each module. Therefore, the VGs effectively cover 12.5% of the back surface of the module, leading to significantly less material use compared to other heat sink approaches.”

The proposed technology was tested in an experimental environment on the roof of a building in Sydney, where the panels had a tilt angle of 30 degrees. Temperature sensors were placed on the back surface of the panels and weather and radiation data were collected via a weather station, while a thermal camera was used to visualize the temperature distribution on the back surface of the modules.

The tests showed that the VGs based on the 3D-printable polymer could reduce the temperature of the modules by up to 1.5 C in high irradiation and low wind, or in southerly winds. The aluminum-based VGs were found to reduce the temperature of the modules by approximately 2 C under high irradiation conditions or by 2.5 C in a high temperature, high wind speed scenario.

“Both VGs perform equally under southerly and westerly winds, indicating the dominance of the vortex generation mechanism,” the group said. “The module equipped with VGs showed an increase in the convective heat transfer coefficient, as evaluated by the thermal balance model.”

The group presented the new cooling technology in the study “Long-term outdoor testing of vortex generators for passive cooling of PV modules”, which was recently published in Solar energy. “In future studies, the correlation between surface flow and freestream wind direction should be verified for a specific type of PV system,” the academics concluded. “Then it becomes possible to optimize a VG for a specific location with a predominant wind direction.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.