In the first term of this two-part series on hail loss prevention, I presented the results of a real-world case study that demonstrated the effectiveness of the solar industry’s hail defenses. Specifically, three projects in Fort Bend County, Texas – Cutlass I, Cutlass II and Old 300 – successfully used defensive hail storage procedures to withstand a range of 1 in 500 year hail events, one of which produced hailstones up to 100 mm. as measured by radar.

The hail defense success stories from Fort Bend County are in stark contrast to the significant damage suffered at the nearby Fighting Jays project, as reported by news media. The effective implementation of operational hail storage protocols explains these very different results. Here, in Part 2 of this series, I’ll provide some best practices for operational hail defense, offering specific, actionable insights proven to protect solar projects from hail damage.

Location risk and project resilience

The foundation of effective hail protection starts with an accurate risk assessment and equipment selection. As a best practice, project stakeholders should require hail monitoring and tracker storage for project sites where the return interval for ≥45 mm hail (as determined by the 95e percentile largest hail diameter) is 100 years or less. This conservative return interval threshold takes into account forecast uncertainties and climate change impacts, which are expected to increase hail frequency in the Northeast and hail size in other regions.

In addition to the hail storm, the selection of PV modules has a significant impact on resilience. The hail durability test results published by RETC show the effect of the glass thickness and strength of the module on hail resistance. Specifically, modules made with 3.2mm fully tempered front glass are approximately twice as resilient to hail as modules made with 2.0mm heat-strengthened front glass. Although 2.0mm bifacial, double-glazed modules are the most common module type in the United States, project stakeholders can improve asset resiliency by installing 3.2mm front-glass modules in hail-prone areas.

Hail warning and response

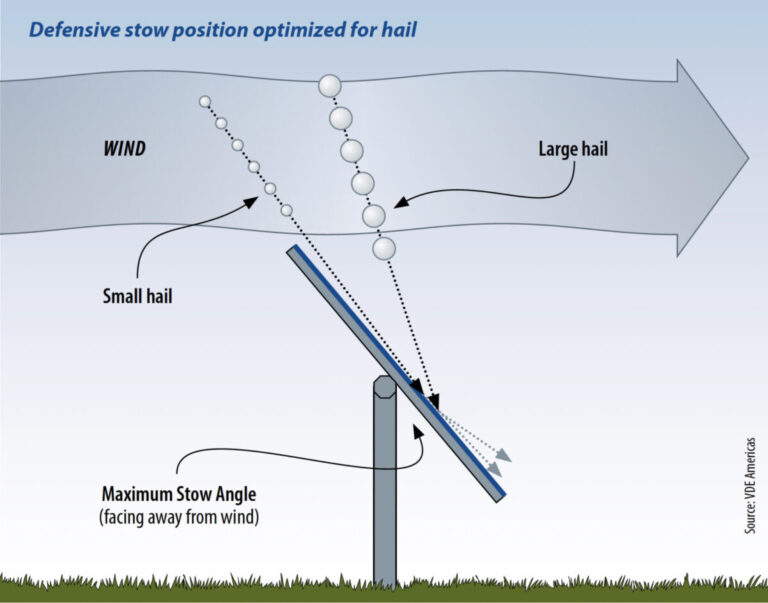

At VDE Americas we recommend a two-level warning system to initiate hailstorms. The first level is a preventive storage response that uses National Weather Service severe thunderstorm warnings and warnings to activate hail storage, in accordance with tracker manufacturer guidelines. All else being equal, hail protection is optimized by moving modules to the highest tilt angle the tracker can achieve, facing away from the prevailing wind direction.

The second level uses specialized alerts from a qualified weather alert service provider to trigger hailstorms to the nearest extreme angle the tracker can reach without passing through the flat position, where modules are most vulnerable to hail damage. As a primary warning threshold, we recommend triggering hailstorms when a storm with a ≥30% chance of severe hail (≥0.75 inches in diameter) is detected within 30 miles. Second, we recommend triggering hailstorms when a storm with heavy hail is detected within a 5-mile radius, regardless of the probability of hail events. To qualify weather warning providers, we recommend a validation study comparing the accuracy and timing of the historical warnings with radar-based observations or on-site hail measurements.

To avoid communication disruptions and critical delays, alerts from weather alert providers should communicate with the project’s SCADA (Supervisor Control and Data Acquisition) system via API integration (not email), preferably at one-minute intervals . Please note that remote operations centers must be staffed at all times and have clear procedures for both automated and manual storage initiation. If automated systems do not respond to a hail warning within one minute, operations center personnel should immediately enable manual backup protocols.

Standard protocols and testing

Site-specific hail storage protocols should include guidelines to minimize risk during construction, when hail monitoring and storage are not yet operational, and during nighttime hours. Although hail is most likely to occur in the late afternoon or early evening, the Fort Bend County case study shows that severe hail can occur at any time. Notably, the March 16, 2024 hailstorm that damaged Fighting Jays hit the project around 2:30 a.m. local time.

The wind direction during hail events is unpredictable and often deviates from the prevailing wind direction. That said, most hailstorms in the continental United States approach from westerly directions. Therefore, east-facing storage is recommended as the standard orientation for preventive storage, overnight storage, and construction storage positions, unless site-specific analysis indicates otherwise.

Due to the serious risk of hail damage to unstored systems, we recommend testing the entire warning and stowage system monthly or whenever changes are made to system components. We also recommend testing as part of commissioning and performance testing prior to substantial completion and final funding. Testing can take place during cloudy conditions or at dawn or dusk to reduce loss of energy production and revenue.

Active storm management

When there is a serious hail risk, a quick response is of the utmost importance. Given that hail has proven to be much more damaging than wind – and damage during the strongest wind events, such as tornadoes, is unavoidable – we recommend that hail stow override the wind gust during active hail warnings.

Contact the equipment supplier to confirm the tracker’s ability to maintain hail position in high winds, based on historical data for the project location. According to the co-probability of wind gust speed and hail size data for Fort Bend County, Texas, for example, a tracker must be able to withstand wind speeds of 67 mph, after applying a safety factor, in a hail thrust position to withstand wind speeds of 55 to 100 km per hour. 65mm hail.

During a severe hail event, operators must monitor the tracker’s position in real time and document any deviations while staying clear. They must immediately investigate storage failures and attempt to resolve them remotely. Finally, they must maintain hail storage for at least an hour after the last weather warning or all-clear warning.

Procedures after a storm

Comprehensive post-storm procedures prove critical to long-term protection through the maintenance, repair and improvement of hail monitoring and containment systems. Sites must deploy at least one hail sensor per square kilometer, integrated with SCADA to record hail characteristics. Hail sensors allow operators to measure the effectiveness of hail monitoring services.

After a hailstorm, teams must collect event-specific forensic evidence, including hail samples (stored in a freezer), weather reports, witness statements, SCADA data, hail sensor data, high-frequency meteorological measurements, and most importantly, wind data. Damage assessment should use both visual inspection with supporting photographs and advanced technologies such as aerial photographs and infrared scanning. This data collection is very useful for warranty and insurance claims.

Contracts, modeling and forecasts

Different providers of weather alerts and trackers have different capabilities and features. Therefore, each project must have its own hail monitoring and stowage protocol. This protocol should be clearly documented in operations and maintenance contracts and operating manuals, with a clear definition of roles, responsibilities and procedures.

It is important to note that while operators can implement best practices for hail protection, they cannot accept unlimited liability for hail damage given the potential magnitude of losses, which can exceed tens of millions of dollars per event. Standard contract termination provisions and performance penalties should apply rather than holding operators liable for the full cost of catastrophic hail damage.

Correctly assessing hail risk in project financial pro formas and downside sensitivity models is a highly effective approach to assessing the adequacy of hail insurance coverage, operating costs for deductible payments or repairs due to losses under the deductible, and outside exposure to confirm insurance coverage. These financial models should include estimates of average annual losses, but importantly, they should also include downside stress testing for the rare scenarios in which very extreme hail events cause damage to hail storage projects and scenarios in which hail storage systems fail.

While we are still working on the best way to do this, the effects of climate change and the El Niño Southern Oscillation (ENSO) cycle must be taken into account to offset estimated losses over the life of a project. We normally see more hail during La Niña years, when the jet stream brings more cold air to the southern part of the United States, where it mixes with warm, moist air from Mexico and the Gulf of Mexico to form more hailstorms.

While we will never be able to claim that we have achieved zero hail risk for solar energy, hail risk mitigation measures continue to evolve through improved materials, forecasting capabilities and refined storage strategies. Fort Bend County’s success stories show that well-implemented protection strategies help prevent hail damage and financial losses.

As our industry continues to prove its ability to mitigate hail risk through comprehensive protocols and rigorous implementation, we are not only strengthening our physical infrastructure, but also strengthening our relationships with insurers and financiers who are wisely assessing and mitigating hail risk start to demand. strategies discussed in this article.

Jon Previtali is a more than twenty-year veteran of the solar industry who has worked in project development, operations, asset management, finance and engineering. He is currently vice president of digital services and product manager for hail risk assessment and mitigation services at VDE Americas.

Read the first article in the series, Storms in Texas show the industry’s solar hail defenses are working.

The views and opinions expressed in this article are those of the author and do not necessarily reflect those of the author pv magazine.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content