Unlocking the potential of lithium-sulfur batteries

Lithium-ion (Li-ion) batteries have become an indispensable part of society, from mobile phones and laptops to electric vehicles. While Li-ion batteries have been a great success so far, scientists worldwide are rushing to design even better batteries that go beyond Li-ion, in the shift to a more electrified world. Commercial Li-ion batteries have a lower energy density than alternative batteries and rely on relatively expensive substances, such as cobalt and nickel compounds, which are also highly dependent on vulnerable supply chains.

One of the promising alternatives to Li-ion batteries are lithium-sulfur batteries (Li-S), which have an anode of lithium metal and a cathode of sulfur. This combination of electrodes promises two to three times higher energy densities and lower costs, while also utilizing Earth’s rich resources.

But these batteries do not come without their own challenges, including short lifespan due to the unwanted migration of polysulfide ions and the uneven distribution and occurrence of chemical reactions within the system.

By developing an innovative electrolyte additive, researchers at the U.S. Department of Energy’s (DOE) Argonne National Laboratory are making progress in addressing these issues limiting the widespread adoption of Li-S batteries.

In Li-ion batteries, lithium ions are stored in the spaces between the layers of the cathode material and move back and forth between the cathode and anode during charging and discharging.

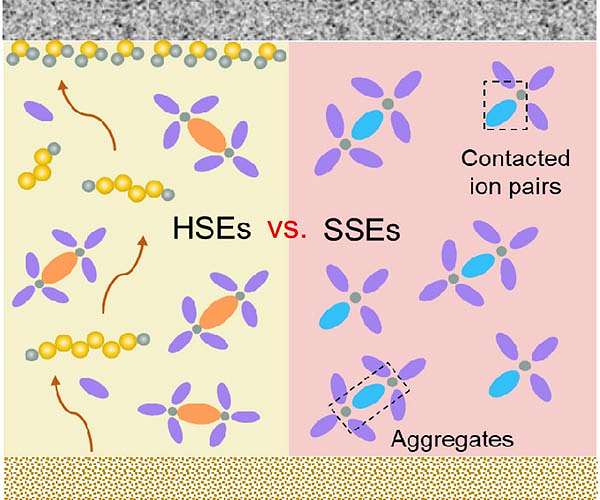

However, Li-S batteries rely on a different process. In these cells, lithium ions move through a chemical reaction between the cathode and the anode. Elemental sulfur from the cathode is converted into polysulfide compounds – composed of sulfur atomic chains – some of which can dissolve in the electrolyte. Because of this solubility, a “shuttling” effect occurs, where the polysulfides travel back and forth between the cathode and the anode. This shuttling results in loss of material from the sulfur cathode as it is deposited on the anode, limiting overall battery life and performance.

Numerous strategies have been proposed to mitigate polysulfide shuttles and other challenges. Such a strategy, which uses an additive in the electrolyte, has long been thought to be incompatible due to its chemical reactivity with the sulfur cathode and other battery components. Argonne chemist Guiliang Xu and his team have created a new class of additives and discovered that such additives can actually improve battery performance. By controlling the way the additive reacts with sulfur compounds, researchers are better able to create an interface between the cathode and the electrolyte necessary to facilitate easy transport of lithium ions.

“The additive, called a Lewis acid additive, is a salt that reacts with the polysulfide compounds and forms a film over the entire electrode,” said Xu. “The key is to have a small reaction to form the film, without a continuous reaction that consumes the material and reduces its energy density.”

The additive forms a film on both the anode and cathode, suppressing the shuttle effect, improving cell stability and promoting a “highway” for ion transport through the electrode. This electrolyte design also minimizes sulfur dissolution and improves reaction homogeneity, allowing the use of additives previously considered incompatible.

To validate the concept, the researchers compared their electrolyte with the additive to a conventional electrolyte used in Li-S batteries. They observed a significant reduction in polysulfide formation. The new electrolyte showed very low dissolution of polysulfides, which was confirmed by X-ray techniques. Furthermore, they monitored the response behavior during charging and discharging of the battery. These experiments used Argonne’s Advanced Photon Source (APS) and Brookhaven National Laboratory’s National Synchrotron Light Source II, both DOE Office of Science user facilities, which confirmed that the electrolyte design minimized the dissolution and formation of polysulfides.

“Synchrotron techniques provide powerful tools for characterizing battery materials,” said Tianyi Li, a beamline scientist at the APS. “Through the use of X-ray diffraction, X-ray absorption spectroscopy and to reduce reactions.”

Xu added: “With further optimization and development of sulfur electrodes, we believe Li-S batteries can achieve higher energy density and better overall performance, contributing to their commercial acceptance.”

Another major challenge for Li-S batteries is the stability of the lithium metal: it reacts easily and poses safety concerns. Xu and his team are working to develop better electrolytes to stabilize the lithium metal and reduce the flammability of the electrolyte, ensuring the safety of Li-S batteries.

At the APS, Beamline 20-BM was used for X-ray absorption spectroscopy to investigate the solubility of polysulfide. Beamline 17-BM was used for X-ray diffraction imaging to examine whole-cell homogeneity or heterogeneity. Beamline 2-ID was used for X-ray fluorescence mapping to confirm the solubility of the electrode material and to observe the migration of sulfur in conventional electrolytes.

Other contributors to this work include Chen Zhao, Heonjae Jeong, Inhui Hwang, Yang Wang, Jianming Bai, Luxi Li, Shiyuan Zhou, Chi Cheung Su, Wenqian Xu, Zhenzhen Yang, Manar Almazrouei, Cheng-Jun Sun, Lei Cheng and Khalil Amine .

The results of this research have been published in Joule. The study was funded by the Vehicle Technologies Office of DOE’s Office of Energy Efficiency and Renewable Energy.

Research report:Polysulfide incompatible additive suppresses the spatial response heterogeneity of Li-S batteries