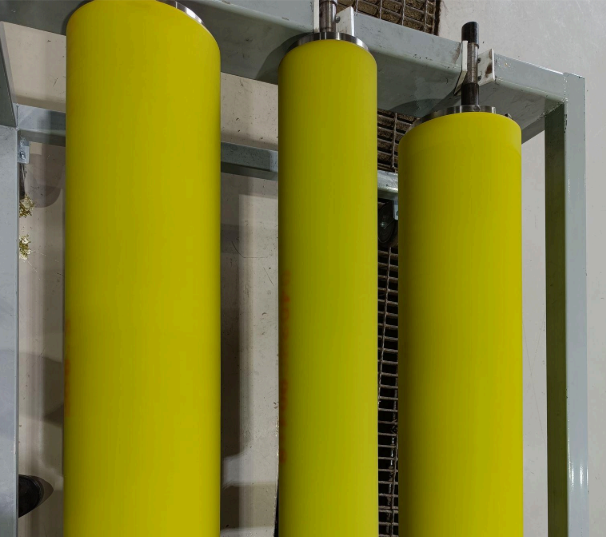

UIS Technologies, a precision technology company based in Penang, Malaysia, has announced the commissioning of its PU solutions for recoating and reprofiling of WGRs at Adani’s 2 GW solar ingot wafer plant in Mundra, Gujarat, India.

WGRs play a crucial role in the silicon ingot cutting phase of the silicon ingot to wafer manufacturing processes. The precise grooving of these rollers has a significant impact on the shape and thickness of the silicon wafers, with even small deviations potentially affecting the efficiency of the solar cells. Given the continuous nature of this process, wear over time results in deteriorating precision of the groove teeth and pitch of WGRs.

Manufacturers are faced with the choice of investing in new WGRs or opting for recoating and reprofiling to extend their lifespan. UIS Technologies offers a turnkey solution for recoating and reprocessing of WGRs at the plant site, with full knowledge transfer to plant engineers so they can use the solution independently in the long term. This means that there is no need for expensive overseas transit of the equipment.

UIS Technologies has long provided these solutions to global silicon wafer manufacturers.

“Recoating and reprofiling of PU can maintain optimal performance for eight to 10 years,” said CT Teh, general manager of UIS Technologies. “After each re-profiling process, WGRs can perform 80 to 120 cuts, depending on the cutting speed in the factory.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.