Kiwa PI Berlin has resolved inverter faults at a PV installation in South Africa through a root cause analysis. The project encountered up to 130 failures involving insulated gate bipolar transistors (IGBTs).

A 95 MW PV plant in South Africa, owned by an independent power producer active in several markets, has experienced recurring inverter failures, according to Kiwa PI Berlin. Between 2022 and 2023, the plant recorded more than 130 failures related to insulated gate bipolar transistors (IGBTs) in field replaceable units (FRUs).

The inverter failures affected both energy production and operational costs due to the need for frequent repairs and replacements. Kiwa PI Berlin was called in to conduct a root cause analysis to identify the underlying issues causing the inverter failures.

Root Cause Analysis is a diagnostic approach used to trace problems back to their origins, enabling targeted solutions and actionable recommendations to prevent recurrence. Inverter problems can occur for a variety of reasons, including faulty printed circuit boards, communication errors, incorrect switching algorithms, inadequate MPPT (Maximum Power Point Tracking) control, and component or maintenance deficiencies.

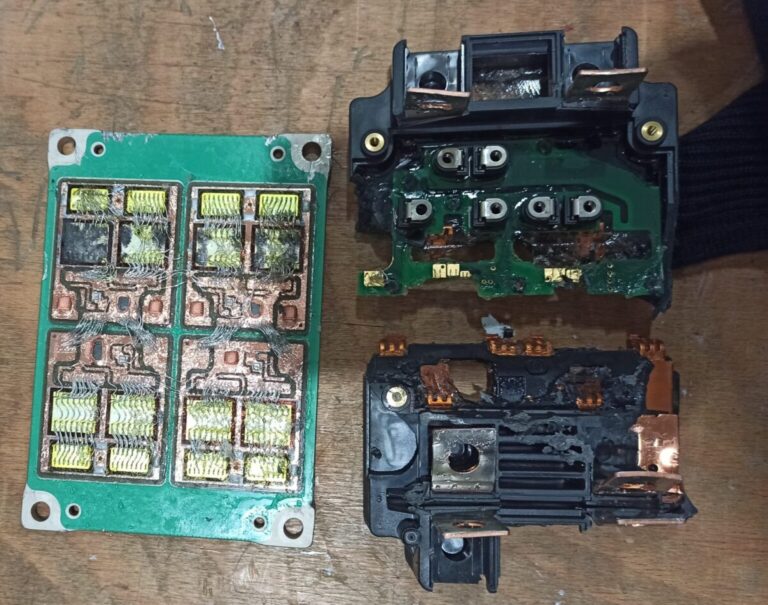

Inverters rely on insulated gate bipolar transistors (IGBTs) to convert direct current (DC) from solar panels into alternating current (AC) for the electrical grid. These components are critical because their malfunction can lead to catastrophic failures, such as explosions or overheating, which can seriously disrupt plant operations.

In response to recurring inverter failures, Kiwa PI Berlin implemented a two-step approach, which included a thorough technical analysis and an on-site analysis. For the technical phase, she assessed all technical documents provided by the client, including data from the SCADA system, previous incident reports and user manuals. Using advanced data analytics and predictive modeling, the team analyzed large amounts of operational and maintenance data to identify patterns and anomalies that contributed to the failures.

During the on-site analysis, Kiwa PI Berlin’s technical team visited the PV installations to physically inspect the inverters, assess environmental conditions and conduct interviews with operators. They collected detailed data on environmental conditions, inverter infrastructure and response actions taken during incidents. To identify switching anomalies, they measured IGBT operations, recorded detailed observations and documented conditions with photographs for further investigation.

The root cause analysis identified multiple factors behind the IGBT failures, starting with defects in one type of field replacement unit (FRU). Although the FRU was able to operate within the safe range for several months, adverse environmental conditions eventually caused the IGBTs to exceed safe parameters, leading to serious failures.

Severe weather conditions, compounded by inadequate maintenance such as faulty fans and loose bolts, further exacerbated inverter problems. The accumulation of dust and dirt on components also led to frequent failures. Manufacturing defects in some components also weakened their performance and durability, leading to repeated IGBT failures.

Based on these findings, Kiwa PI Berlin has made several targeted recommendations to improve the operation of PV installations and prevent future failures. It proposed a stricter maintenance schedule to ensure components operate under optimal conditions, focusing on regular fan checks, cleaning of sensitive parts, continuous inverter monitoring and periodic reviews of cooling systems to address problems before they escalate.

Kiwa PI Berlin worked with the manufacturer to improve the robustness of the FRU by eliminating previously discovered defects. It also recommended integrating advanced SCADA systems for real-time monitoring of inverters, with additional sensors and monitoring software to closely monitor operating conditions and identify potential faults early.

Garikoitz Sarriegi, senior project manager at Kiwa PI Berlin, explains pv magazine that “the plants have achieved a significant reduction in inverter failures and a noticeable improvement in operation and performance.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.