Researchers in China have manufactured an aluminum contact-based top-cone sun cell that has achieved a power conversion-efficiency of 22.92%. The device is built with an aluminum contact production process that reportedly does not endanger the quality of the surface passion of underlying silicon oxide layers.

A group of researchers led by the University of New South Wales (UNSW) in Australia has developed a tunnel oxide -passivated contact (Topcon) -Zonne -Zon based on aluminum (already) contacts placed on the back.

“The proposed cell configuration is aimed at replacing expensive Silver (AG) pastas used for cell contacts by cheap aluminum, which can be seamlessly integrated into the existing industrial screenshot infrastructure and is already well established in the production of solar cells,” tells the main author of the examination, told, PV -MagazineState that already pastes costs around $ 3-7/kg, which is more than 100 times cheaper than silver (AG) pastas and is considerably cheaper than emerging buyer (CU) pastas.

In the newspaper “Integration of aluminum contacts in Topcon sun cells: a route to reduce silver use“Published in Solar energy materials and solar cellsThe scientists explained that they already used contacts prepared with a loose tool (laser contact opening (LCO). The contacts were then screen printed with a conventional al -pasta supplied by the Japanese specialist Toyo Aluminum KK

“Although the laserblation step would include an extra capex and opex, many manufacturers already manufacturers (LCO) tools for perc-cell production. These tools can be reused for our process, making it both cost-effective and compatible with the current production-setups,” Song added.

The process was implemented without jeopardizing the quality of the underlying surface -passion quality Silicon oxide (poly-si/siox) Layers and with the Al -Fingers are printed and fired with the aluminum paste on the back surface of the cells. “Although the Al particles penetrated deep into the poly-si layer, they did not reach the Poly-SI/SIO2 Interface, maintaining the surface passion, “they emphasized.

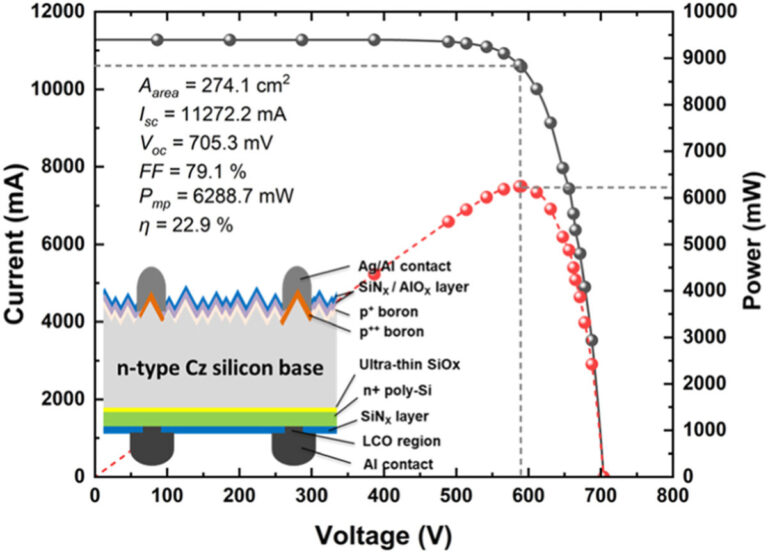

With this rear cell architecture, the research team built various Topcon sun plums with a shooting temperature of 680 ° C. The performance of these cells was then compared with those of reference Topcon devices with AG contacts and metallization.

“With the optimum shooting condition and LCO pattern design, the manufactured rear-al-champion cell has achieved a promising efficiency of 22.9% within an efficiency gap of 0.8% with the AGE-AG reference cell,” the team said. “Our findings emphasize the need to minimize Al/Poly-Si contact recovery and resistance losses to effectively reduce the efficiency gap with the reference cell.

Looking forward, Song said that more efforts will be spent on reducing the efficiency gap between aluminum and silver contacts. “That said, we are open to collaborations and we see a strong potential for partnerships with manufacturers who are interested in using more sustainable and cost -effective solutions for metallization,” he concluded.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.