Japanese scientists built a thin-film perovskite solar cell in which fluorinated phosphoric acid (TPFP) was incorporated into the absorber precursor solution. The device achieved remarkable energy conversion efficiency due to effective passivation at the interface between the perovskite film and the hole transport layer.

Researchers from Saitama University in Japan have fabricated a thin-film perovskite solar cell based on fluorinated phosphoric acid passivating additives and mixed solvents for passivating halide defects.

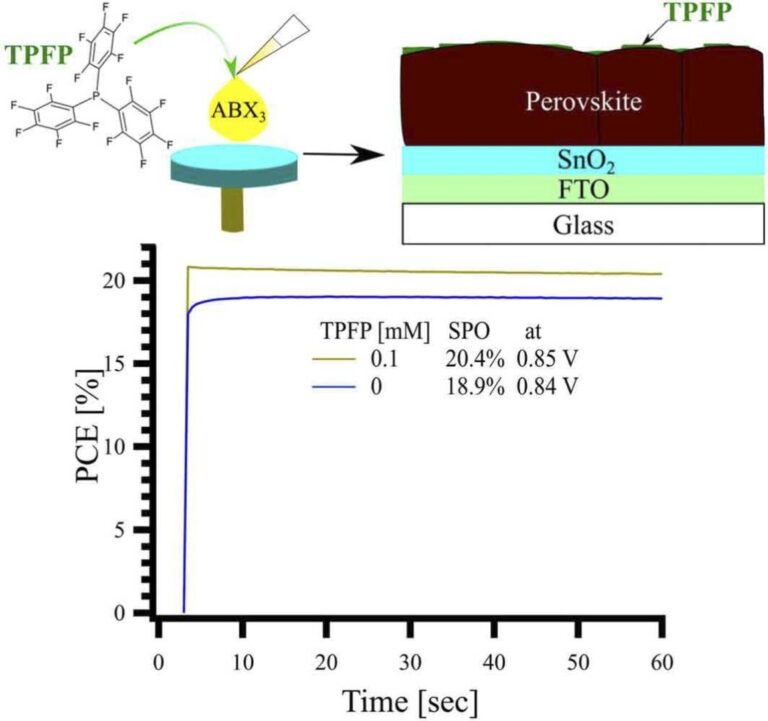

“Rather than relying on traditional surface treatments, the method directly integrates fluorinated phosphoric acid (TPFP) into the perovskite precursor solution,” the research team explains. “TPFP’s inherent low surface energy facilitates its self-assembly and segregation on the perovskite surface during film formation, resulting in a passivating layer.”

In the study “Fabrication of efficient methylammonium-free perovskite thin-film solar cells without post-treatment and anti-solvent,” published in Following materialsthe scientists explained that the solar cell does not contain methylammonium (MA) molecules. These molecules have intrinsic thermal instability and contribute to increasing the typical thermal instability of perovskite PV devices.

They also explained that the cell manufacturing process does not require post-treatments and anti-solvents, due to the surface segregation of TPFP. “A 0.1 mM or 0.2 mM solution of TPFP in chlorobenzene was poured onto the perovskite layer at 3000 rpm before deposition of the HTL,” she added. “TPFP underwent self-segregation during film formation due to its low surface free energy and aggregation on the perovskite surface.”

The group built the cell with a glass substrate and fluorine-doped tin oxide (FTO), a tin oxide (SnO2) electron transport layer (ETL), a perovskite absorber, a hole transport layer (HTL) based on Spiro-OMeTAD and a silver (Ag) metal contact .

Tested under standard lighting conditions, the device showed an energy conversion efficiency of 20.5%, an open-circuit voltage of 1.04 V and a short-circuit current density of 25.9 mA/cm2and a fill factor of 76.2%. For comparison, a reference cell without the TPFP treatment achieved an efficiency of 18.9%, an open-circuit voltage of 1.03 V, a short-circuit current density of 25.4 mA/cm2and a fill factor of 76.3%.

The TPFP cell also reportedly showed reduced hysteresis and improved stabilized power.

“The approach could go beyond spin coating,” the researchers said, hinting at future directions of their work. “It could be applicable to printing techniques such as squeegee and slot die coating, which are better suited for large-area deposition processes.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.