Researchers from Norway and Germany investigated the influence of impurities in fused quartz crucibles used in the production of silicon PV rods. The results suggest that the most important factors affecting crucible uniformity are sand quality, sand particle size and aspects of the manufacturing process.

Researchers from Norway and Germany investigated the influence of impurities in fused quartz crucibles used in the production of silicon PV rods, particularly the physical properties and uniformity of hydroxyl impurities.

The research was made possible by infrared microscopy and viscosity testing.

“Understanding the weaker points in the structure of the crucible could potentially lead to its improvement,” corresponding author, Gabriela Kazimiera Warden, said pv magazine. “We believe that our research should be of interest to crucible manufacturers as it shows that some aspects of the manufacturing process can influence the final properties of the crucibles. It is also relevant for them to understand the quality of the billet, its contamination and what to expect during the use of the crucibles.”

The raw material used in the Czochralski crucibles is natural quartz sand (SiO2) that has been processed to a purity of 99.997%. The performance of a crucible depends on properties, such as viscosity, which in turn depends on the presence of impurities, such as the content of hydroxyl groups (OH), the researchers said.

Too much OH leads to low viscosity. “It is preferable that the crucible has a high viscosity, which implies greater mechanical stability at higher temperatures, and therefore leads to better durability. This means that the crucible can be used for longer,” they emphasized.

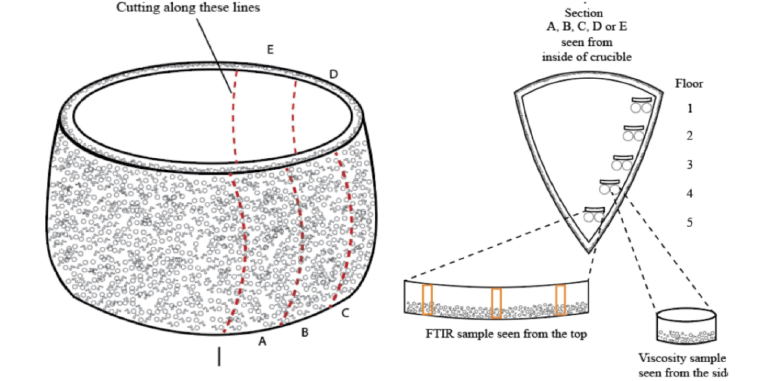

In the experimental setup, half of a molten quartz crucible made from two types of sand was studied. Samples were taken from the crucibles and prepared for the viscosity test and IR microscopy examination. Typically, OH groups are present in quartz sand used in the fusion process and in water inclusions.

When investigating the distribution of the OH groups in the crucible, an attempt was made to identify any weak areas in the crucible. The content of OH groups was mapped and the viscosity at 1500 C was measured. “Local variations in the content of OH groups of an average of 26.7 ppm difference between the top and bottom of the crucible were detected,” the researchers said.

The viscosity measurements further confirmed the inhomogeneity of the crucible, as there are no clear trends or direct correlations with the contents of the OH groups, the team said.

In addition, four samples from four different crucible types were also examined. The samples from different crucibles were taken out and all characterized on the same layer.

The researchers examined the differences between the crucibles and attributed them to the different sand purification treatments. In two of the crucibles, the team observed an increased content of OH groups in the boundary between the bubble-free and the bubble-containing layer, while others showed an increased and maximum OH group content in the bubble-containing layer.

Moreover, the relationship between the sand types and the content of OH groups was confirmed.

“The source of the local inhomogeneities and the two different trends in the distribution of OH groups can possibly be attributed to the sand quality, the sand particle size and the difference in the production process, such as the thermal history or the distribution of sand,” the researcher said . researchers.

The differences in the distribution of the OH groups were “most likely” related to the different process conditions, including the thermal history, of the vacuum and sand distribution, the quality of the sand used and the particle size of the sand, they noted.

A further correlation they found was between the type of sand used to make the crucible and the final content of OH groups, which they said could affect the viscosity of the crucible.

“Both the chemical treatment and the differences in chemical size have a significant influence on the final OH group content, which was found to be lowest in the crucible melted with refined quartz sand alone, followed by a mixture of fine and coarse, and the highest in the crucibles made from coarser sand,” the team concluded.

And finally, the researchers emphasized that “contrary to previous studies” they could not see a clear correlation between the content of OH groups and the viscosity values within the variations in the content of OH groups in the samples. “This further proves that the crucibles are not uniform and that viscosity is influenced by more factors than the content of OH groups,” they said.

The research is described in detail in “Investigation of uniformity in quartz crucibles for Czochralski silicon rods”, published in Journal of Crystal Growth.

The team came from three Norwegian organizations: the Norwegian University of Science and Technology (NTNU), research institute SINTEF Industry and The Quartz Corp, plus the Germany-based Max Planck Institute for Sustainable Materials.

Looking ahead, Warden said there is “much still to be explored,” for example the potential influence of trace elements on the properties of the crucible.

“We hope that our research will draw some attention to the importance of high-quality quartz crucibles for the production of monocrystalline silicon. We look forward to more groups getting involved in research into this material as we believe it is crucial to improve productivity and thus reduce the cost of the blocks, making solar energy more affordable and reducing the amount of waste reduced.” she said.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.