German supplier of photovoltaic thermal (PVT) modules Sunmaxx PVT and planning company for regenerative energy systems good energy recently conducted a new, comprehensive feasibility study on decarbonization with solar energy technologies at a 17,000 m² production site of automotive supplier MAHLE. The study shows that heat and electricity demand at the MAHLE site can be completely decarbonized through the combination of PVT and standard PV modules.

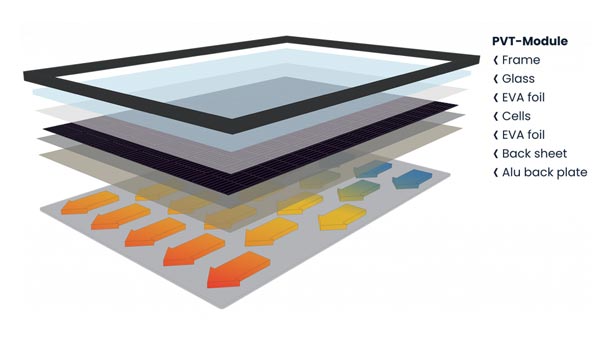

By using PVT modules, geothermal probes and a geothermal heat pump, the production site can significantly reduce its CO2 footprint and save costs. These modules can produce heat and electricity at the same time.

Part of the heat generated by the modules is stored seasonally in the geothermal field, while part of the roof surface is already sufficient to generate the entire annual heat demand of the location via PVT modules. Standard PV modules are used to generate electricity in the remaining unused parts of the factory. This combination of energy generation not only maximizes efficiency, but also reduces CO2 emissions2 emissions by approximately 2,700 tons per year.

Thanks to Sunmaxx’s PVT modules, the required number of ground probes could be greatly reduced. In addition, the ground probes serve as seasonal storage, which absorbs the solar heat from the PVT modules in the summer and releases it for heating purposes in the winter. This results in a win-win situation in the interaction of the two components, ground probes and PVT, making the concept technically and economically successful.

– says Dr. Markus Pröll, project manager and authorized signatory at Goodmen Energy.

Sunmaxx’s solution has the potential to revolutionize virtually any sector, providing a fully scalable and customizable solution for businesses with significant energy needs. The company works with highly energy-intensive industries to decarbonize locations with hundreds of GWh of heat and power demand.

“Combined with modern heat pump technology, we can instantly cover temperature ranges up to 150°C and significantly reduce fuel costs, even at higher temperatures. And even without geothermal energy, sites can be completely or largely decarbonized with our modules,” says Dr. . Wilhelm Stein, CEO of Sunmaxx PVT.

The project is currently in the implementation phase and is expected to be commissioned in 2024. Meanwhile, a team from Sunmaxx PVT and MAHLE is working intensively to decarbonize other MAHLE sites in the same way.