The researchers outlined a ‘scalable’ production process that reportedly results in a tungsten diselenide film with an efficiency of up to 22.3%. The proposed technique could facilitate the mass production of high-efficiency multilayer WSe2 solar cells at low cost.

A group of researchers led by Stanford University has developed a new manufacturing process to build transition metal dichalcogenide (TMD) solar cells in a scalable manner, bringing them closer to commercial production.

TMDs are two-dimensional materials with remarkable semiconducting properties and high optical absorption coefficientficents. This makes them suitable for the production of semi-transparent and flexible solar cells with potential applications in aerospace, architecture, electric vehicles and wearable electronics, where low weight, high power-to-weight ratio and flexibility are highly desirable.

“We have developed a scalable, mass production-friendly method that yields photovoltaic-quality tungsten diselenide (WSe) at wafer scale.2) films with a layered Van der Waals structure and superior characteristics, including charge carrier lifetimes up to 144 ns, more than 14 times higher than other large-area TMD films previously demonstrated,” said the corresponding author of the research, Koosha Nassiri Nazif, narrated pv magazine.

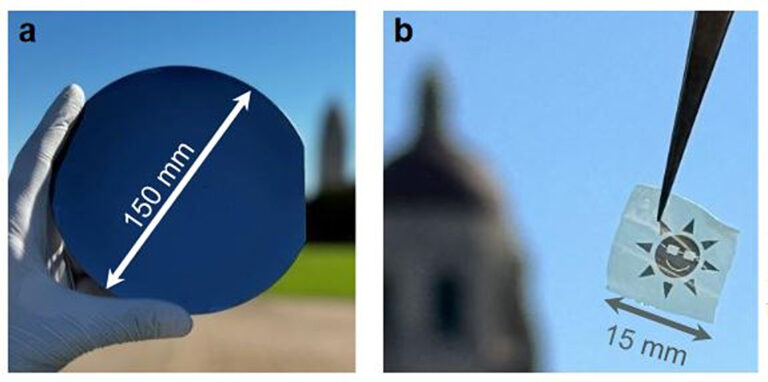

The group designed a sputtered multilayer WSe2 film with a thickness of 15-30 nm for applications on a 150 mm wafer via a solid source selenium (SS-Se) selenization process at 900 C or low thermal budget. hydrogen seleniated (H2Se) precursors at 650 C. The resulting WSe2 film had an energy band gap of 1.2 eV to 1.3 eV, which the scientists described as almost ideal for solar energy harvesting.

The film reportedly exhibits superior properties compared to previous reports of selenization, as well as smooth and uniform surfaces. According to the researchers, with improved contacts and doping it could achieve an efficiency of up to 22.3% in an optimized solar cell design.

“Our realistic models show that the lifetime of such carriers corresponds to an energy conversion efficiency of approximately 22% and approximately 64 W g–1 specific power in a packaged solar cell, or about 3 W g–1 in a fully packaged solar panel. The results of this study could facilitate the mass production of high-efficiency multilayer WSe2 solar cells at low costs”, Nassiri Nazif declared.

The new cell concept was described in the article “Towards mass production of transition metal dichalcogenide solar cells: scalable growth of photovoltaic-grade multilayer WSe2 by tungsten selenization”, which was recently published in ACS Nano. The research team included academics from the University of Colorado Boulder and the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), as well as Hasselt University and the University of Antwerp in Belgium.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.