This type of solar cell technology had so far achieved an efficiency of up to 9%. The new result was made possible by an in situ passivation strategy after deposition to reduce surface defects in the device, its creators said.

Silver bismut sulfide (AgBiS2) Nanocrystals (NCs) are a material common in the Earth that has been used in recent years as a promising PV material, often in combination with cadmium sulfide in the development of various types of ultra-thin solar cells.

Solar cells built with these nanocrystals have so far achieved efficiencies of up to 9%, and their overall optoelectronic properties appear to change dramatically as their composition and size change. Their fabrication can be performed in air at low temperatures using low-cost solution processing techniques and low-cost production equipment. Furthermore, AgBiS2 NCs have very low toxicity compared to other materials used for thin-film solar cells, such as cadmium telluride and cadmium sulfide.

With this in mind, researchers from the Institute of Photonic Sciences (ICFO) in Spain have fabricated an AgBiS2 PV device exceeding the 10% efficiency threshold for the first time.

“AgBiS2 has recently been published as a promising ternary semiconductor that is free of toxic heavy metals and has been shown to possess extraordinary optical properties, including the highest optical absorption of any other photovoltaic absorber,” says the lead author of the study. Gerasimos Konstantatos, narrated pv magazine. “That resulted in an energy conversion efficiency of more than 9%, which was achieved using a layer-by-layer solid-state ligand exchange process that is, however, not suitable for large-scale, large-area production required for PV deployment.”

The 9% efficiency threshold refers to an efficiency of 9.7% AgBiS2 solar cell developed with an energy-efficient and scalable annealing process by the same ICFO in early 2022.

According to Konstantatos, ink technology is the best choice for solution processed nanocrystals/quantum dot optoelectronics and solar cells to enable economies of scale and large-scale production. However, to date, existing ink technologies have failed to deliver AgBiS2 photovoltaic solar energy with an efficiency of more than 7.5%.

“We have developed a new ink formulation technology by designing a multifunctional molecular agent that serves a dual purpose, because firstly it allows extremely good dispersion of the nanocrystals in the ink, which is of utmost importance for achieving high-density thin films morphological quality, and secondly, upon thin film formation and mild annealing process, the ligand dissociates and delivers chloride ions onto the surface of NCs that passivate the remaining cationic surface sites. This additional passivation takes place on the spot and this is crucial to ensure uniform passivation throughout the film.”

The research group presented the new post-deposition technique in the study “Post-impeachment on site passivation of AgBiS2 nanocrystal inks for highly efficient ultra-thin solar cells”, which was recently published in Energy and environmental sciences. “This strategy leads to NC thin films with convincing optoelectronic properties with very low trap-state density and high and balanced carrier mobility,” emphasizes Konstantatos.

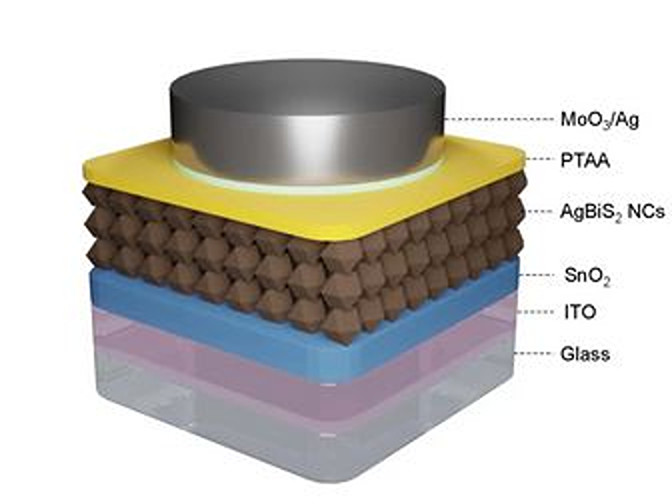

The academics constructed the cell with a substrate of glass and indium tin oxide (ITO), an electron transport layer (ETL) of tin oxide (SnO2), the AgBiS2 absorber with embedded NCs, a hole transport layer (HTL) based on poly(triarylamine) (PTAA), a buffer layer made of molybdenum trioxide (MoO3) and a silver (Ag) metal contact.

Tested under standard lighting conditions, the cell achieved an energy conversion efficiency of 10.84%, an open-circuit voltage of 0.511 V, a short-circuit current density of 29.15 mA/cm2 and a fill factor of 72.8%. In comparison, a control device fabricated without the proposed passivation strategy achieved an efficiency of 7.75%, an open-circuit voltage of 0.476 V, a short-circuit current density of 24.98 mA/cm2, and a fill factor of 65.1%.

The researchers said the efficiency improvement was mainly due to a significant increase in short-circuit current and fill factor, with the new passivation strategy responsible for homogenizing the cation disorder, which they said improved absorption coefficients and optoelectronic properties. They also found that unencapsulated cells exhibited ‘stable’ shelf life under ambient conditions for more than 145 days and continuous operation at maximum power point (MPP) for more than 10 hours.

“We believe that our work will generate further interest and attention for the development of environmentally friendly materials and that our ink formulation process may find applications in other quantum dot or nanocrystal material systems for photovoltaics or optoelectronics in general,” Konstantatos concluded.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.