Silk thread innovation stimulates smart textile technology

Imagine a sweater that can generate power for health monitoring electronics or charge your cell phone while you exercise. This has remained a challenge because materials that are both effective conductors and suitable for textiles are difficult to find. Researchers at Chalmers University of Technology in Sweden are now exploring a new approach using a plain silk thread coated with a conductive polymer, which holds promise for transforming fabrics into electricity generators.

Thermoelectric textiles can convert the temperature difference between the human body and the surrounding air into electrical energy, which can be used to power sensors without batteries. Such sensors can track body movements or monitor heart rate, offering applications that benefit daily life and healthcare. To meet practical requirements, these materials must be safe, flexible and lightweight, especially when worn close to the skin.

The Chalmers team used silk thread coated with a conductive plastic polymer. This specific polymer structure allows it to conduct electricity while maintaining the comfort and flexibility necessary for wearable textiles. “The polymers we use are flexible, lightweight and can be used in both liquid and solid form. They are also non-toxic,” explains Mariavittoria Craighero, a doctoral student at Chalmers University and lead author of the study.

A major improvement over previous research was the elimination of metals, which had been used to improve the material’s stability in air. Instead, the new wire uses exclusively organic, carbon-based polymers to achieve both improved conductivity and stability. “We have found the missing piece of the puzzle: a newly discovered polymer that provides exceptional stability in air while maintaining high conductivity. Importantly, our approach avoids rare earth metals, which are common in electronics,” said Craighero.

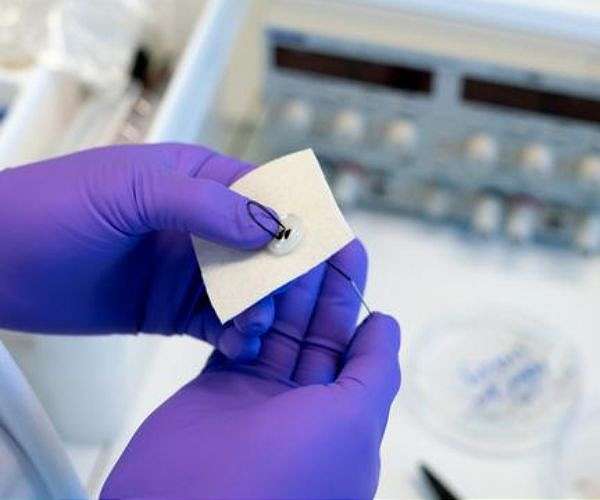

To demonstrate its practical usefulness, the researchers produced two thermoelectric generators: a button and a piece of textile sewn with the coated wires. When these generators were placed between a hot and cold surface, they showed a voltage increase depending on the temperature difference and the amount of conductive material.

For example, a larger piece of fabric produced about 6 millivolts when exposed to a temperature gradient of 30 degrees Celsius. Theoretically, a voltage converter could use this energy to charge portable devices via USB. Notably, the wire retained two-thirds of its electrical properties even after seven machine washes, which Craighero said was a promising result, although further improvement is needed before it goes to market.

Scaling up production is the current challenge because the conductive wire is still made by hand in the laboratory. Making a textile with the conductive side took four days of hand sewing. Despite this limitation, Christian Muller, professor at Chalmers and leader of the research, highlighted the potential of the innovation: “We have shown that conductive organic materials can meet the functional requirements of thermoelectric textiles. This is an important advance that paves the way for future applications with significant societal benefits.”

Research report:Poly(benzodifurandione) coated silk yarn for thermoelectric textiles