Scientists in Finland have built a perovskite solar cell with a bio-inspired coating that reportedly improves light transmission while also having self-cleaning properties. The film was able to improve the efficiency of the device by up to 6%.

A research team from Aalto University in Finland has developed a perovskite solar cell based on a ‘light management layer’ made from a polymer material with the surface of leek leaves, which can reportedly improve the device’s efficiency by as much as 6%.

The scientists explained that the bio-inspired layer has self-cleaning properties. “The self-cleaning of the films can maintain the efficiency of the panels over time by washing away dirt and dust that can block light,” said researcher Hamidreza Daghigh Shirazi of Aalto University in a study behind the paper. article published by Springer nature.

“In terms of optical properties, the replicated films exhibit high overall light transmission, and in addition, the structure of the film contributes to the forward scattering of light, which is also known to improve the efficiency of some solar energy technologies.”

To create the film, the researchers used a substrate fabrication method that replicates the surfaces of each leaf or patterned surface on cellulose acetates (CA). They initially examined a variety of plants and replicated their surface structures in cellulose films.

“Although the exotic lotus leaf is often a source of bio-inspiration for self-cleansing, many common garden plants, such as leeks, possess desirable surface properties,” they noted. “Leek has self-cleaning leaves thanks to the microstructure of the surface and the natural wax layer. This combination allows water droplets to roll off easily, removing dust and dirt.”

The group used leek leaves measuring 5 cm x 5 cm as a mold master. Then, a monomer-to-crosslinker known as polydimethylsiloxane (PDMS) was poured on top, followed by curing at room temperature and a tuning step to adjust the cellulose acetate solutions at three different concentrations.

To achieve the desired level of hydrophobicity necessary for efficient self-cleaning, the scientists added a bio-based carnauba wax (CW), which is said to be the hardest natural wax with the highest melting point among commercial plant waxes.

The leek leaf replicas were then glued to the glass substrate of the cell. Immediately after drying, the IV characteristics were measured. The means and standard deviations were then reported for each sample from seven devices.

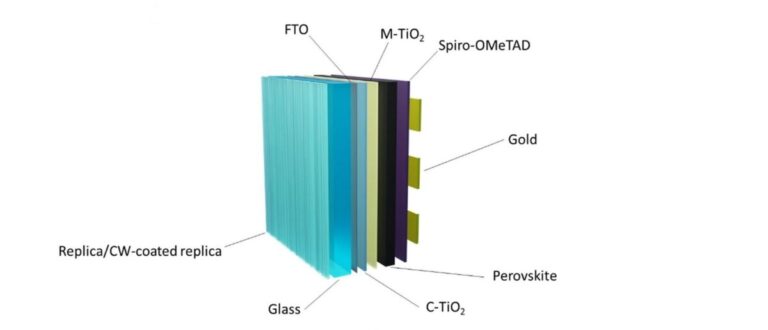

The academics built the solar cell with a substrate made of glass and fluorine-doped tin oxide (FTO), covered with the new film. an electron transport layer (ETL) made of titanium oxide (TiO2)a perovskite absorber, a hole transport layer (HTL) based on Spiro-OMeTAD and a gold (Au) metal contact.

The cell was then tested under standard lighting conditions and its performance was compared to that of a reference device without the replica film. The coated cell achieved an energy conversion efficiency of 14.2%, an open-circuit voltage of 1.07 V, a short-circuit current density of 18.7 mA cm−2, and a fill factor of 71.0%. The reference device achieved an efficiency of 13.4%, an open-circuit voltage of 1.05 V, a short-circuit current density of 18.3 mA cm−2 and a fill factor of 69.2%.

“Despite the lower transmittance of the CW-coated replica, in a trade-off between optical transparency and superhydrophobicity/self-cleaning ability, the developed films as a light management layer can guarantee solar photovoltaic performance over time,” the scientists said. “Meanwhile, the water-repellency of the surface facilitates self-cleaning, ensuring maximum incident light in the long term by tackling dirt accumulation.”

The details about the new film and the solar cell architecture can be found in the paper “Bio-inspired surface structures promote optical transmission and hydrophobicity in cellulose-based films for self-cleaning perovskite solar cells,” published in Communication materials.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.