A Japanese-Italy research team says they have developed a simple and convenient method for recovering copper wires from PVC cables, using microwave radiation and avoiding the formation or use of toxic chemicals.

Scientists from Sophia University in Japan and Università di Pavia in Italy have developed a microwave-induced pyrolysis method to recycle VVF power cables.

The research paper “Recycling of electronic waste power cables using microwave-induced pyrolysis – process properties and ease of recovery of copper metal”, published in the magazine RSC Progress, say Electrical wiring cables, consisting of copper or aluminum wires, pose a significant waste problem, despite being highly recyclable. It adds that the recycling rate for PVC insulation material is currently only around 35%, with the majority ending up in landfills.

“VVF cables are often used as power cables in homes and buildings and have a high reuse value among electronic waste,” said Satoshi Horikoshi, one of the lead authors of the study. “Our method is suitable for recycling and recovering e-waste containing metals and does not require any pre-treatment to separate the plastics from the metals.”

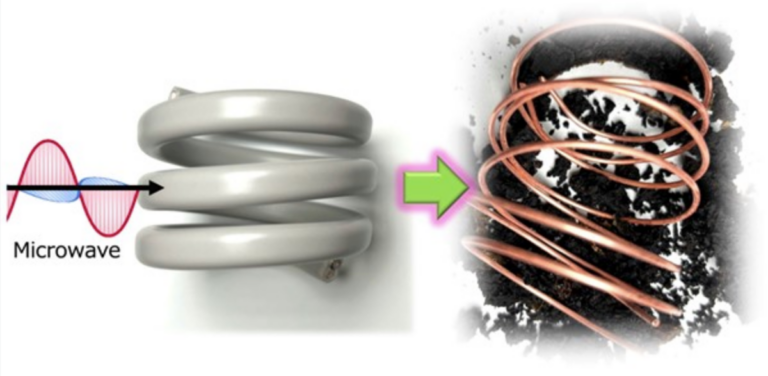

The method developed by the researchers consists of placing VVF power cables in a glass reactor where they are exposed to microwave radiation. The pyrolysis carbonises the PVC insulation, exposing the copper wire and making it easy to recover.

In the study, the researchers tested a standard 54 cm VVF cable and cut pieces of different cable lengths, measuring 1 cm, 6 cm, 9 cm, 12 cm and 18 cm. They were then exposed to microwave radiation of 100, 200 and 300 W.

The team found that the effectiveness of the pyrolysis varied with the cable length in relation to the wavelength of the microwave, which was about 12.24 cm at a frequency of 2.45 GHz.

Pyrolysis was most effective in cables whose length corresponded to specific fractions of the wavelength. The 9 cm, equal to about 3/4 wavelength, and 18 cm cables, longer than the wavelength, started to pyrolyze after 60 seconds at 100 W. The 3 cm cable, equal to about 1/4 wavelength, started to pyrolyze at 200 W.

Other lengths of 1 cm, 6 cm, and 12 cm, which represented whole or near whole wavelengths, showed no pyrolysis at 300 W.

Since the microwave demonstrated the ability to heat and break down wires longer than the wavelength, the 54 CM VVF cable was found to be completely pyrolyzed in 12 minutes under 300 W radiation, leaving the copper wire intact and undamaged.

This was achieved without the production or use of toxic chemicals. The researchers explain that the PVC insulation underwent rapid dichlorination and carbonization during pyrolysis, preventing the formation of harmful byproducts such as tar, polycyclic aromatic hydrocarbons and dioxins.

“It is clear that microwave-induced pyrolysis has proven suitable for recycling/recovery of e-waste-containing metals and does not require any pretreatment to separate the plastics from the metals,” the researchers said.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.