Scientists from Denmark examined three facades installed on a mobile office container to conduct building-integrated PV experiments.

Researchers from the Technical University of Denmark (DTU) built a photovoltaic test site (BIPV) integrated into the building and monitored it for a year to analyze the yields of different types of panels. They focused on BIPVs with different colors and rear ventilation configurations. The test site also included a section with differently structured front glass and a module with back-contact (IBC) cells, the results of which will be published at a later date.

“The basic construction consists of a mobile office container with a footprint of approximately 3 x 9 meters. Prefabricated curtain wall elements consisting of an aluminum frame with 200 mm mineral wool insulation were then installed as an outer wall,” the researchers explain. “On elements where PV modules with rear ventilation are mounted, a thin fiber cement board provides wind and weather protection for the insulation material. Non-ventilated PV modules are mounted directly against the insulation as a rain screen and secured with aluminum frames that are integrated into the curtain wall structure.”

16 uncolored modules have been mounted on the south side of the container to test the ventilation effect. For the modules without rear ventilation, the distance to the insulation varied between 0, 10, 20 and 30 mm. The rear ventilation modules were mounted on horizontal brackets, with air gaps of 50, 100, 150 and 200 mm for natural rear ventilation.

Image: Technical University of Denmark, Energy and Buildings, CC BY 4.0

Five differently colored modules and a reference module without an air gap are mounted on the west facade. For them, pigment-based colored interlayers were laminated with an additional encapsulating layer between the cell matrix and the front glass. The colors used were red, gray, green, beige and terracotta. The panels were monitored between September 1, 2022 and August 30, 2023.

Image: Technical University of Denmark, Energy and Buildings, CC BY 4.0

“On the west facade, the reference and green modules have the lowest annual DC performance ratios (PRs) of 0.86, the gray, beige and terracotta have slightly higher annual DC PRs of 0.88 to 0.89, while the red module has a significantly higher annual DC performance ratio (PRs). DC PR of 0.95,” the academics said. “The higher PR for the red module can be partially attributed to spectral mismatch gains in the afternoon, which can be as high as 10% in the evening.”

An analysis of the operating temperatures for the south facade showed a 40% to 50% lower temperature difference with the environment for externally mounted modules with rear ventilation compared to insulated modules. The annual performance ratio of the better ventilated modules was found to be on average 6% pt higher.

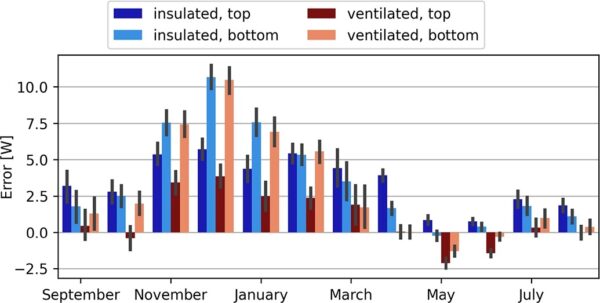

After obtaining the results from the ventilated and unventilated sides of the container, the same facade was simulated in the National Renewable Energy Laboratory’s (NREL) System Advisor Model (SAM) in an attempt to identify errors in the models using this software . “Four scenarios are simulated using data from modules S2 (insulated top), S6 (insulated bottom), S9 (200mm air gap top) and S13 (200mm air gap bottom), as they represent the most extreme mounting configurations for both top and bottom rows,” they explained.

The results showed a good agreement between the modeled and measured irradiance data, with the exception of some periods in the morning and evening.

“In terms of operating temperatures, SAM can predict the temperature of ventilated modules quite well on clear-sky days, but for insulated modules the modeled temperature can be about 10 K lower than measured,” they concluded. “On occasionally cloudy days the model performs significantly worse, although the transient thermal model correction in SAM does reduce the error. Finally, a general overestimation by SAM was noted for the DC yield, which is significantly higher in the winter months compared to the summer months.”

Their findings were presented in “Yield analysis of a BIPV facade prototype installation”, published in Energy & Buildings. The underlying data set is published that researchers can use in model validation.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content