Scientists in South Africa have modeled a photovoltaic system connected to a thermoelectric cooling device and found that without cooling it can produce about 9.2% more electricity than a conventional PV system. The research team claims that the proposed system guarantees a minimum cost saving of 10.56%.

A group of researchers from the Central University of Technology in South Africa have designed a solar panel that integrates a cooling system that uses a thermoelectric cooler (TEC).

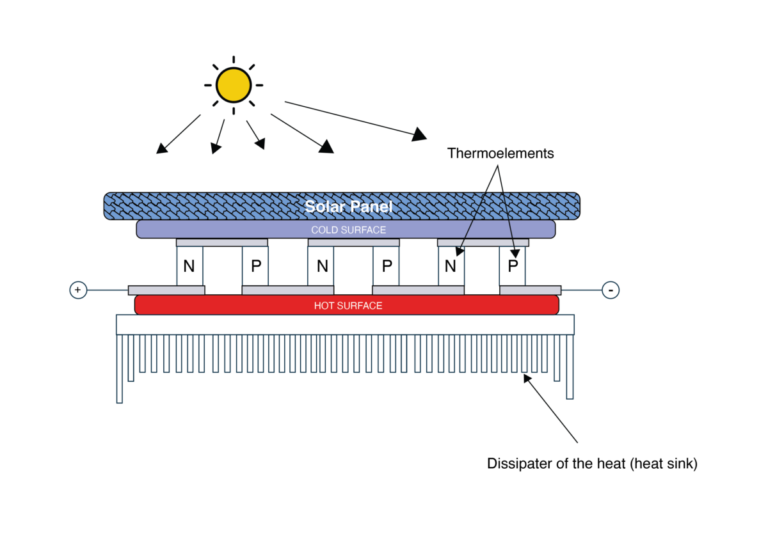

TECs can convert heat into electricity via the ‘Seebeck effect’, which occurs when a temperature difference between two different semiconductors causes a voltage between the two substances. The devices are often used for industrial applications to convert excess heat into electricity. However, its high cost and limited performance have so far limited its wider application.

“The PV-TEC system proposed in this study includes a PV panel integrated with a TEC device, attached to the back, a heat sink connected to the opposite side of the thermoelectric device, and a switching mechanism ”, the scientists explained. “The TEC is powered by the PV panel that has to cool it.”

The group conducted a numerical simulation to assess the system’s performance. In addition, an optimization function was set to maximize output while maintaining a target temperature between 23 C and 27 C when the cell temperature exceeds 25 C. The PV panel used in the simulation had an output of 100 W, an efficiency of 17.8% and a size of 20,200 cm3. The TEC had a maximum current of 6.1 A, a maximum voltage of 17.2 V and a size of 6.08 cm3. The heat sink had a thermal resistance of 2.6 C/W and a size of 39.2 cm3.

“The scenario under consideration involves the use of meteorological data obtained from Bloemfontein, Free State, South Africa,” the researchers said. “The specific data set includes diffuse horizontal, diffuse normal and global horizontal irradiance, along with ambient temperature values, delineating a typical winter day on July 17, 2021 and a summer day on January 17, 2021.”

The operation of the system was analyzed for both a summer day and a winter day and its performance was compared to a reference PV panel without the TEC and heat sink. Under the simulated winter conditions, the cell temperature never exceeded 25 C, so the TEC was not active. Therefore, in both the PV-TEC case and the reference case, the peak temperature was recorded at 22.9 C, the constant output power was 86.9 W, and the total energy production was 363.47 Wh.

However, in the summer the TEC came into action and allowed the panel to reach a peak power of 104.1 W, compared to 94.4 W in the reference case. The peak temperature in the reference was 36.1 C, while the PV-TEC did not exceed 25 C. In the TEC case it achieved an energy yield of 603.60 Wh, compared to 547.65 Wh in the reference. “The results of our proposed model showed a substantial improvement in power output, especially by 9.27% during summer,” the academics pointed out.

Based on these results, the researchers proceeded to conduct an economic analysis with an assumed lifespan of 20 years for the PV and the PV-TEC, as well as an annual increase of 10% in electricity prices and an interest rate of 6%. While the initial price of the 100W solar panel alone was assumed to be ZAR 1,235 ($66.9), the total cost for the PV-TEC housing was ZAR 1,562.77.

“The break-even point manifests itself relatively early in the operational life of the project. To be precise, it happens after 6.5 years,” the scientists concluded. “The economic analysis further resulted in a cost saving of R2,905.61, which is a saving of 10.56% over the life of the project over a 20-year period.”

The system was presented in “Improving the efficiency and cost-effectiveness of the photovoltaic control system through optimal control of the thermoelectric cooling,” published in Solar energy materials and solar cells.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.