Sandia Evaluates Heat Shields for Mars Sample Return and Titan Missions

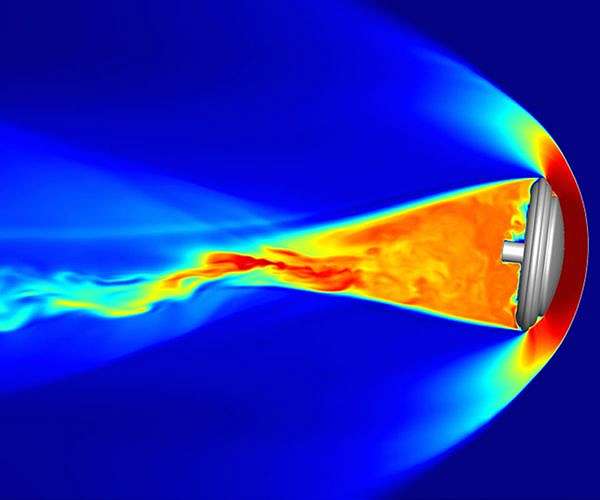

Sandia National Laboratories’ National Solar Thermal Test Facility uses solar energy to simulate the intense heat experienced during atmospheric reentry and hypersonic flight. The latest tests are intended to support NASA missions, including the Mars Sample Return Campaign, a joint effort with the European Space Agency to bring rock samples from Mars to Earth for analysis. These samples could reveal evidence of ancient life and help prepare for future human missions to Mars.

As part of the Mars Sample Return mission, a Sample Retrieval Lander would carry the heaviest payload ever sent to Mars, along with a rocket to launch the collected samples into Martian orbit. Heat shield materials for the lander were recently tested at Sandia, said Sandia engineer and test director Ken Armijo. “This would be the first mission to return rocks from Mars to Earth; it has a larger payload,” Armijo explained. “The heavier the payload and the larger the entry vehicle, the hotter the vehicle gets during atmospheric entry and the better the heat shield needs to be.”

Sandia’s solar testing facility uses hundreds of heliostat mirrors to focus sunlight on samples up to a meter wide, simulating atmospheric conditions on different planets. Unlike arcjets and lasers, which consume significant power, this approach saves between 15,000 and 60,000 kilowatts per test, equivalent to running 5,000 to 20,000 clothes dryers simultaneously.

The facility’s solar power tower, 60 meters high and equipped with 212 heliostats, provides a unique environment for testing materials under high solar flux and heat. “We have high flux and high flux distribution on the solar tower,” Armijo said. The facility can simulate hypersonic flight conditions and house large test samples, including entire aircraft sections. Sunlight is concentrated to 3,500 times normal intensity, allowing precise control over heat exposure.

Compared to the $100,000 per day cost of arc beam testing and the $150,000 per day cost of laser testing, solar testing costs about $25,000 per day, Armijo noted. The intensity of sunlight can be adjusted by varying the number of heliostats aimed at the sample, simulating different reentry conditions. NASA’s lead engineer for the Sample Retrieval Lander heat shield, Brandon Smith, noted, “Sandia’s ability to test at this scale nicely complements our other test facilities.”

Testing also supports NASA’s Dragonfly mission to Titan, Saturn’s largest moon, with heat shield materials made from phenolic-impregnated carbon ablator developed at NASA’s Ames Research Center. The material was previously used in missions such as Stardust and Mars 2020 and was tested at Sandia on samples measuring two feet wide. The facility’s ability to test larger samples allowed NASA to simulate the stress and strain experienced during atmospheric entry.

Dragonfly, a helicopter aircraft designed to explore Titan’s methane-rich atmosphere, faces unique challenges due to Titan’s dense atmosphere, which is four times thicker than Earth’s. To simulate the thermal conditions of entering the atmospheres of Mars and Titan, nitrogen gas is blown over the heat shield samples during tests. A newly installed gas line running from the base to the top of the power tower provides adequate gas flow, Armijo said.

Daniel Ray, a mechanical technologist at Sandia, was responsible for setting up the gas line and troubleshooting problems during testing. “My role on any project is to make sure it works,” Ray said. He solved a problem where the carbon felt caught fire by designing ceramic shields to protect the system.

In 2022, Sandia also supported the Applied Physics Laboratory’s tests on a prototype heat exchanger intended for future spacecraft. The prototype endured light levels equivalent to 2,000 suns and reached temperatures of 3,100 degrees Fahrenheit, demonstrating its ability to withstand the intense heat of a nearby solar flyby.

The facility’s history includes several space projects, such as testing radar protection domes and evaluating materials for space shuttles and military aircraft. Sandia has refined its solar testing methods over the years, Armijo says. “Being able to dial in the profiles gives us more confidence that it will survive and function properly on a mission. It’s important to be confident that it will reach Mars, land and pick up the rocks safely.”