Saipem, an Italian oilfield service provider, has developed a floating offshore PV platform in collaboration with its Norwegian unit Moss Maritime.

Italian gas contractor Saipem has deployed a new offshore floating solar panel near the island of Froya in the Norwegian Sea, near Trondheim.

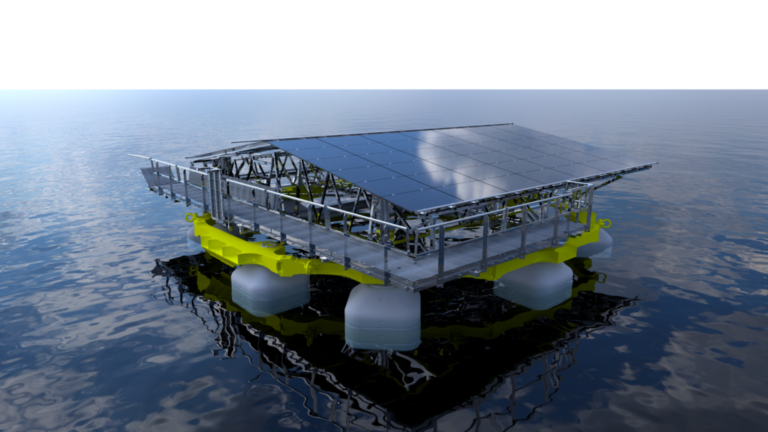

Saipem’s Moss Maritime unit developed the XolarSurf prototype with Norway-based Kystteknikk Maritime Service AS. The system is built to withstand waves up to 8 meters high.

“These waves can be found, for example, in much of Southeast Asia, the coastal areas of the Mediterranean, the Gulf of Guinea or the Middle East,” said Ida Husem, CEO of Moss Maritime. pv magazine. “For locations with more challenging environments, such as the North Sea, we have developed XolarSurf Generation 2, which is based on the same principles as Generation 1, but has a more robust structure. For quieter locations, a scaled-down version of XolarSurf may be applicable.”

The prototype consists of floats, a frame, a PV mounting structure and electrical equipment such as PV panels, inverters and wiring.

“An island will consist of several individual floats connected by self-lubricating rotating joints,” Husem said. “The individual floats can rotate freely relative to each other, causing the island to behave like a floating carpet above the incoming waves. The size of an island depends on local site conditions and customer requirements. For larger farms, multiple islands are sufficient – the number of floats per island and the number of islands in a farm can be adjusted to suit any capacity need.”

The installed capacity per platform depends on the size of the floats, but also on the arrangement, size and capacity of the solar panels.

“The recently launched prototype has a power of 35 kW to 45 kW, according to Husem. “However, panel efficiency is increasing rapidly and typically, and based on the efficiency available today, a panel can have a capacity of 700W, which represents a significant increase in the capacity per float already available. ”

The companies conducted resistance and stress tests of the float-to-float connector in the laboratory and large-scale tests of the docking procedure in open water.

Husem noted that the system can be hybridized with offshore wind turbines, as both projects can share infrastructure for electricity transmission and joint O&M activities. She said the wind-solar duo offers a more balanced production profile. On sunny days the wind is often limited, while on windy days the sun can be limited, she explains.

The prototype is the result of years of development, design, laboratory testing of models and components and large-scale maritime testing by Saipem, Moss Maritime and Norway’s Equinor.

“We have been in contact with several potential customers over the past few years, some of whom we are currently evaluating future collaborations with us,” said Husem.

Husem noted that the aquaculture sector is well suited to the proposed platform as it relies heavily on diesel generators, with the majority of energy consumption going to feeding fish. She added that the platform can also supply electricity to remote areas or serve as a hybrid solution with offshore wind energy.

The test phase will last a year. Husem emphasized that in addition to testing, work is also underway to develop XolarSurf Generation 1, designed for semi-hostile environments, and Generation 2 for more extreme conditions. As part of the transition to a commercial product, pilot projects of 0.5 to 1 MW are planned.

Moss Maritime, a 100% subsidiary of Saipem, owns the XolarSurf technology and is currently responsible for all offshore floating solar developments within Saipem.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.