Researchers from the University of New South Wales have used a 1µm copper flat layer on the silver grid of a Topcon solar cell to create a protective barrier that reportedly reduces susceptibility to corrosion. The cell showed significantly lower contaminant-induced degradation than unprotected reference devices.

Scientists from Australia’s University of New South Wales (UNSW) have attempted to reduce contaminant-induced degradation in solar cells based on tunnel oxide-passivated contact (TOPCON) technology using copper (CU) plates on screen-printed devices.

According to the research group, their work Not only improves the reliability and durability of topcon cells under moisture heat (DH) and field-like conditions, but also highlights the potential for reducing silver consumption and lowering the level of electricity (LCOE).

“Our work specifically addresses an important challenge: the susceptibility of topcon cells to corrosion, especially during pre-metallization,” the study’s lead author Bram Hoex said. PV magazine. “To mitigate this problem, we introduced a 1 µm Cu plating layer on the silver grid, creating a protective barrier that significantly reduces the susceptibility of the corrosion. By performing our experiments at the cell level, instead of the module level, we were able to speed up the testing process by up to two orders of magnitude. This allowed us to obtain faster results and perform detailed failure analysis, which significantly improved the efficiency of our research and development cycle. ”

The researchers explained that plated CU contacts capped with silver (Ag) or TIN (SN) are used to prevent contaminants themselves from infiltrating the contacts and causing oxidation, and to improve the soldering process in topcon cells.

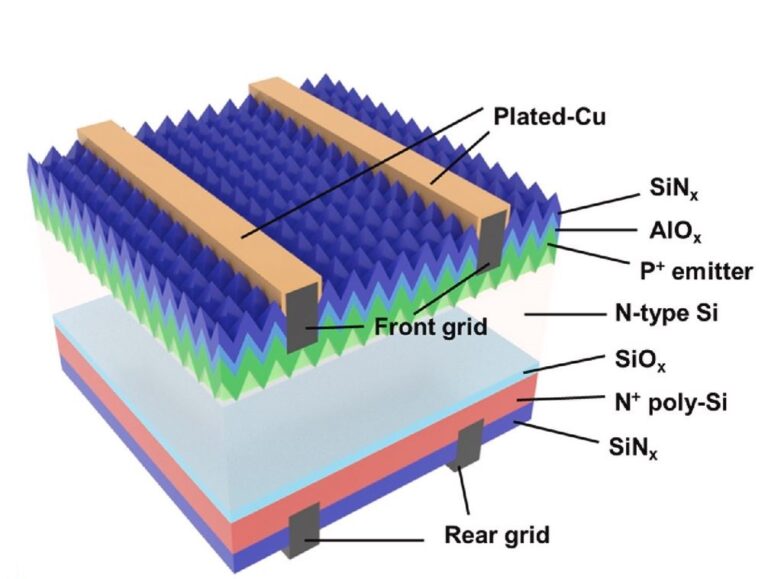

In their experiments they used bifacial nine-busbar (9bb) 158mm Topcon solar cells based on carrier-selective passivating contacts (CSPCs) made of polysilicon and silicon monoxide (poly-sioX)) and a screen-printed silver grille on the back, as well as on a boron-doped emitter passivated with aluminum oxide (ALOX) and silicon nitride (sinX) and another screen-printed silver grille on the front.

The plating process, which can result in Sodium chloride (NaCl) induced degradation In TopCon devices, especially in the front, screen printed solar cells were done using a conifer plating tool. “During the plating process, the back side made full contact with the cathode electrode and the front side was immersed in the plating solution (CUSO4),’ said the academics. “A bias-assisted light-induced plating (LIP) was applied with a constant current and illumination of approximately 150 ma during the process.”

The tests showed that THe flat cells showed an initial efficiency improvement of approximately 0.39% REL, attributed to reduced grid resistance and increased fill factor.

“After 6 hours of DH testing, unprotected cells showed greater than 80%REL efficiency degradation, while CU-plated cells maintained performance with only approximately 11.5%REL efficiency loss,” Hoex explained. “Transfer Length Method (TLM) measurements revealed a 10-fold increase in contact resistance for bare cells within just 0.5 hours of testing, while CU-plated cells maintained much lower resistance levels over extended testing periods.”

Furthermore, scanning electron microscopy (SEM) and energy dispersive

“Given the results of this accelerated test, we conclude that the gold-plated CU layer can effectively alleviate NaCl-induced degradation under DH conditions and greatly improve the stability of the device,” the scientists concluded. “The contact resistance of NaCl-exposed bare cells was already 1 to 2 orders of magnitude higher than that of plated cells after just 2 hours of DH testing, accounting for most of the loss in fill factor.”

Their findings are available in the study “Alleviating Contaminant-Induced Degradation of Topcon Solar Cells with Copper Plating” Published in Solar energy materials and solar cells.

The research work Builds on some of the team’s previous work, including one demonstrating the degradation of industrial Topcon solar cells subjected to accelerated test conditions of 85 C and 85% relative humidity under the so-called moist heat test (Dh85) and another presents and another presents how to present a laser how to present a laser how to present a laser -Assisted shooting process can increase contact quality and corrosion resistance in topcon devices, while also reducing production costs.

This content is protected by copyright and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.