Researchers in India have demonstrated a wet chemical process to recover high-purity silicon from discarded solar panels, which they used to make functionalized silica nanoparticles. Tests on the incorporated nanoparticles in anti-corrosion coatings showed a corrosion protection efficiency of 99.5%, which they claimed was a 200 times lower corrosion rate compared to uncoated silica nanoparticles.

Researchers in India have demonstrated a wet chemical process to recover silicon material from dismantled solar panels at the end of their life.

To validate the usefulness of the recovered silicon, the scientists produced functionalized silica nanoparticles, which were then used as anti-corrosion coatings in a polymer. Test results showed a corrosion protection efficiency of 99.5%, which they claim is an approximately 200 times lower corrosion rate compared to uncoated silica nanoparticles.

The scientists noted that their easy wet chemical process for recycling EoL panels focused on Aluminum Back Surface Field (Al-BSF) type panels, as most current and future EoL panels will be of this type.

“We have demonstrated an efficient, environmentally friendly, sustainable, circular economy-based strategy for managing the globally growing waste streams of EoL solar panels,” said Parveen Saini, corresponding author of the study. pv magazine. “It was a challenge to recover silicon solar cells encapsulated between the top and bottom ethyl vinyl acetate (EVA) polymer plates, without burning the EVA.”

The team used solvents for the EVA removal step, which presented another challenge to overcome: preventing loss of used medium or solvents and subsequent regeneration for reuse.

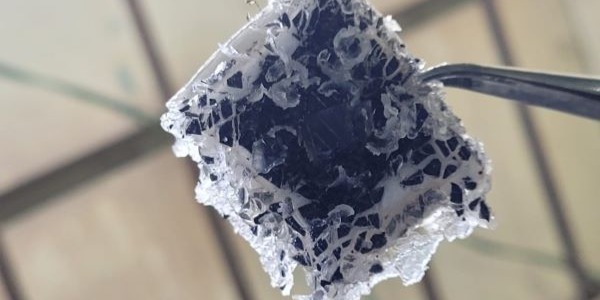

According to the study, the recovered cells were exposed to successive chemical treatments to selectively etch out different layers, such as the top silver finger contacts, the top anti-reflective coatings and the bottom aluminum contact layer. The component materials, such as silicon cells, cover glass, bond wires and polymer layers were separated to expose the bare silicon wafer. It had a purity of over 99.9%.

Recognizing that the recovered silicon could not be reused for solar silicon production, the team decided to use it to create silica nanoparticles, optical-quality hydrophilic silica nanoparticles with optimized functionality.

The team used ground silica powder as a precursor to synthesize the silica nanoparticles, which were chemically functionalized into silica (SNP) and hydrophobic silica (HSNP) nanoparticles in a three-step process. The SNPs and HSNPs were then characterized based on structural, morphological, optical and spectroscopic techniques.

The HSNPs were used as anti-corrosion coatings and they performed “significantly” better than conventional coatings based on both plain polymer matrix and uncoated nanoparticle-filled polymer composites. The corrosion inhibition efficiency was 99.5% and the corrosion rate was approximately 200 times lower compared to the uncoated silica nanoparticle-filled polymer coating, the team said.

The performance was attributed to the nanoparticles’ ability to minimize water absorption and effectively prevent corrosive substances from reaching the substrate.

The research is described in “A facile waste-to-wealth approach for the synthesis of functionalized silica nanoparticles from discarded solar panel waste for technological applications”, published in Resources, conservation and recycling.

The HSNP recovery process has already attracted attention beyond academia. “People from the corrosion industry and specialty coatings industry have shown interest in the recovery and repurposing,” Saini said.

Looking ahead, the research team plans to scale up and adapt the nanoparticle process by redesigning it – or reducing the steps – to better fit existing value chains and targeted applications. Further efforts are underway toward the “conversion of these particles into industrially useful end products,” Saini said.

The researchers were from the Academy of Scientific and Innovative Research (AcSIR), the CSIR-National Physical Laboratory and the University of Delhi.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.