Queen Mary scientists work together with Power Roll to promote Perovskite Solar Technology

Queen Mary University of London has joined forces with innovative Solar Startup Power Roll to switch Perovskite Sun film from laboratory research into large -scale application.

Perovskite is generally considered the future of solar energy because of its lightweight, flexible and highly efficient properties, making installations in locations that are not suitable for conventional silicon panels.

Traditional solar panels based on silicone are rigid and heavy, limiting installation options. Almost 30% of the commercial roofs worldwide cannot support their weight, which contributes to the fact that only 2% of the buildings worldwide use solar energy. This is despite the fact that the sun provides enough energy in one hour to provide the world with electricity for a year.

In addition, the production of silicon panel carries a considerable carbon footprint and 91% of these panels comes from China, so that the vulnerabilities of the supply chain are presented for countries aimed at diversifying energy sources.

However, the potential of Perovskite is impeded by production -challenges. The attributes that make it an attractive alternative to silicon also complicate large -scale production, with defects in manufacture that form the largest obstacle for widespread adoption.

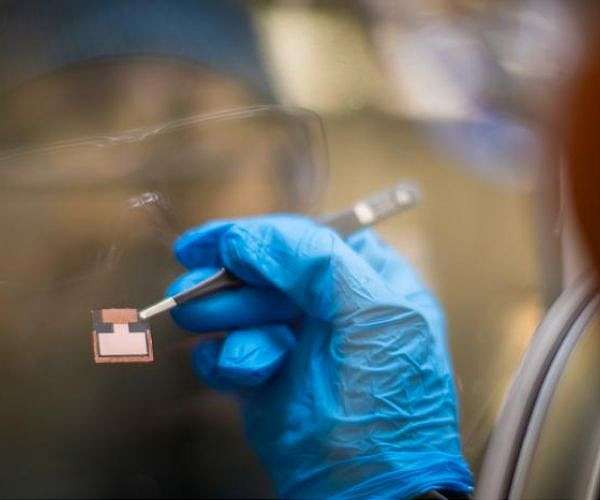

Power Roll has developed an innovative approach with the help of microgrooves and vacuum formation to produce ultra -thin perovskiet film without millimeter thick and 25 times lighter than the lightest silicon panels. This miniaturization makes quality control particularly challenging, because each individual solar cell is 1/50th of the width of a human hair, making visual inspection impractical.

Queen Mary Scientists, led by Dr. Stoichko Dimitrov, develop advanced in-situ optical analysis technology, which will integrate Power Roll into its production process to improve quality control and research efforts.

Dr. Dimitrov explains: “The technology will analyze how light interacts with the material as it is produced, thereby offering essential data for monitoring and improving the quality of the film produced in real -time. This allows Power Roll to scale up production and make Perovskite film a reality.”

Dr. Dimitrov was the first to develop portable in-situ optical analysis technology to improve the performance of printed photovoltaic perovskiet materials. This partnership marks the first industrial application of technology and speeds up the optimization process further than traditional research and development time lines.

Dr. Dave Barwick, Technical Manager at Power Roll, adds: “Quality control is the key to changing the PEROVSKITE from concept to reality. We are proud to work with Queen Mary University of London to achieve this.”

He continues: “We make solar energy that goes where other solar solutions cannot do, and we do it without using rare and costly earth materials. The expertise of Queen Mary in optical analysis will help us scale up the production by ensuring that every microscopic solar cell is of the highest quality.”

The implications for both the environment and the economy are considerable. This lightweight perovskiet film can be used in numerous locations and previously unlocked solid solar potential. Power Roll estimates that only the UK has 12 billion square meters with low load-bearing roofs that are able to host solar energy systems. If used, these roofs can generate renewable electricity at a quarter of the current grid costs, which represents a market opportunity of around 250 billion pounds.