Scientists in Morocco have designed a photovoltaic-thermal panel that uses a channel-box heat exchanger consisting of 94 channels connected directly to the PV module. The simulated design reportedly results in an overall panel efficiency of more than 90% and good results in terms of temperature inhomogeneity.

A group of scientists led by Chouaïb Doukkali University in Morocco has designed a photovoltaic-thermal solar panel based on a duct box heat exchanger, aimed at improving convective exchange.

They explained that the proposed design offers the advantage of having the entire panel surface in direct contact with the fluid, while plate and tube PVT modules provide a small contact area between the plate and the tube. “In addition, this proposal seeks to solve the problem of temperature inequality, which affects the durability of PV panels,” she added.

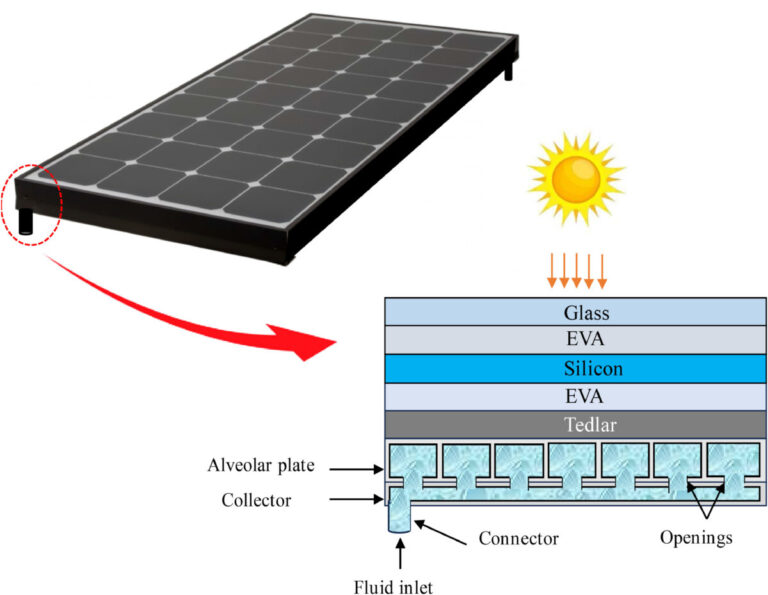

The proposed heat exchanger includes three zones for coolant inlet (AZ), heat exchange (ZE) and liquid evacuation (VZ), respectively. It uses water as a coolant, which flows through the heat exchanger to utilize the heat produced by the PV module. “The EZ consists of an alveolar plate, consisting of a flat top wall in contact with the back of the PV module, and a bottom wall,” the group specified. “These walls have a thickness of 0.4 mm, which allows optimal heat transfer between the PV module and the circulating coolant within the channels.”

The heat exchanger is divided into two zones: a solid aluminum zone and a liquid zone where water flows into the solid zone. The PVT panel also contains a photovoltaic module, a Tedlar layer, two transparent layers of ethyl vinyl acetate (EVA) and a glass cover plate.

Using the COMSOL software, the research team ran a series of simulations to assess the system’s performance based on solar radiation and volumetric flow rate. It was believed to be in a stable state and no dust accumulated on its surface. The analysis also took into account parameters such as solar cell temperature, coolant outlet temperature, cell efficiency and yield, as well as thermal energy recovered, thermal efficiency and overall efficiency.

“In COMSOL, PVT and PV modules are joined together using a physically controlled mesh sequence,” the academics explain. “This approach results in a gradual increase in the number of lattice elements at each limit, allowing precise resolution of heat transfer phenomena and flow fields.”

The simulations showed that flow rate is a key factor for panel performance, with each 10 l/h increase in fluid flow reducing the solar cell temperature by approximately 0.885 C, which in turn results in an increase in power output of approximately 0.798 W. Furthermore, each increase in fluid flow by 10 l/h increases cell efficiency by approximately 0.051%.

The PVT panel was also found to achieve electrical, thermal and overall efficiency of approximately 12.11%, 78.59% and 90.7% respectively. “When the flow rate and inlet temperature are kept at 180 l/h and 29 C respectively, the total system efficiency increases from 83.15 to 90.7% while solar radiation increases from 2 x 10 °C.2 to 103 W/m2. So for every increase of 102 W/m2 in terms of solar radiation, there is a 0.94% improvement in overall efficiency,” the academics pointed out.

The system was introduced in the newspaper “Numerical study of a photovoltaic-thermal (PVT) hybrid water-based solar collector with a novel heat exchanger”, which was recently published in e-Prime – Advances in electrical engineering, electronics and energy.

“The proposed PVT-C provides good results in terms of temperature inhomogeneity and overall performance,” the scientists concluded. “In this context, it will be worth recommending the realization of this new PVT-C, which can be easily integrated into the building and adapted to air or water needs depending on the seasons and thermal requirements off the building.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.