Researchers in Niger have proposed using photovoltaics to power the operation of evaporative cooling greenhouses. The proposed experimental solution uses locally made pads and is said to be competitive with commercial counterparts.

A group of researchers from Abdou Moumouni University in Niger has proposed using photovoltaics to power evaporative cooling greenhouses (ECGs) in Africa’s Sahel region.

ECGs are a kind of greenhouse that cools the plants using the natural evaporation process. The evaporation process is carried out by pumping water onto special wet pads while fans push air through them.

“Under dry and hot weather conditions in the Sahel, cooling is necessary to maintain a favorable microclimate,” the research group explains. “To avoid a conventional costly and unsustainable cooling system in the Sahel, where the air conditioning is connected to the electricity grid or via generators powered by carbonated fossil fuels, a self-contained photovoltaic system was used to power the evaporative cooling system , i.e. the water pumping and distribution and the fans. .”

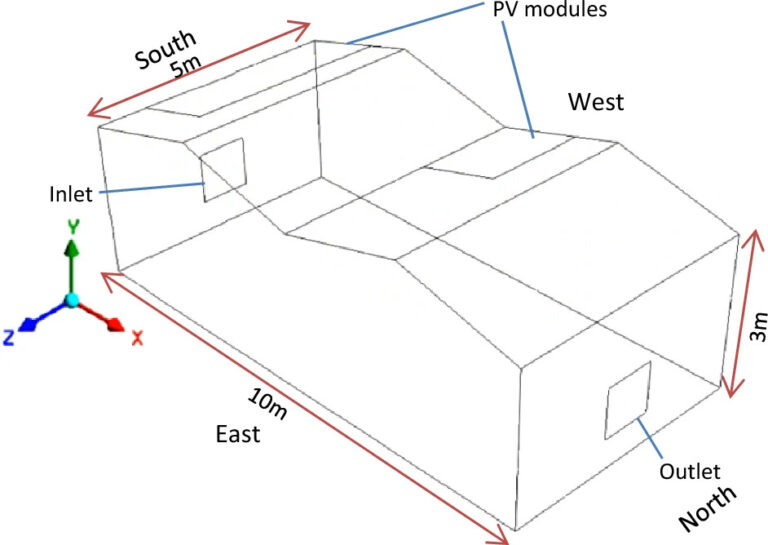

The test setup was located in the south-west of Niger and covered an area of 50 m2, with a height of 3.66 m and a roof slope of 15 degrees. The water pumps and fans were powered by six PV modules with a power of 260 W each, using a 5 kVA inverter. Four batteries of 150 Ah each were also used to allow smooth operation in the absence of irradiation.

As for wet sanitary napkins, the academics compared two different types in the same system. One was the commercially available Celdek pads (C-pads), the other was locally made Hyphaene thebaica fiber pads (HF pads). In both cases, partitions have been placed along the greenhouse walls, with one fan per path.

“Climatological parameters recorded in situ and thermophysical data obtained at laboratory prototype level and from the installed PV ECG were used to assess the alternative HF-pad cooling potential over conventional C-pad,” the academics explained. “The key cooling performance of the greenhouse is derived from established thermodynamic energy and mass balance equations.”

Additionally, after collecting the data from the real greenhouse and conducting a laboratory examination of the pads, a computational fluid dynamics (CFD) analysis was performed to gain an overall understanding of the coolant distribution in the greenhouse. Both the numerical model and experimental data collection were conducted in the hot and dry seasons, with input temperatures ranging from 35 C to 45 C and relative humidity ranging from 10% to 15%.

“Cooler using HF pad makes it possible to maintain the microclimate below 25 C, with maximum humidity up to 80%, under harsh environmental conditions,” the team emphasized. “HF-pad had the highest cooling performance coefficient (COP = 9 vs. 6 for C-pad), the best cost-efficiency ratio (CER = 5; 4 times less than C-pad) and the lowest exhaust temperature (20.0 C).”

The scientists also highlighted that the C-pad cooler, thanks to its higher exhaust air velocity, spread cool air up to 1.25 m further than its counterpart, creating a higher pressure in the atmosphere, with twice the turbulent kinetic energy.

The group concluded that the HF pad achieved cooling performance that rivaled conventional pads. “Optimization of the HF pad frame technique and scaling up the technology to industrial levels can enable better thermal and economic performance,” she added.

Their findings were presented in “Improving the sustainability and effectiveness of photovoltaic evaporative cooling in the Sahel,” published in Scientific reports.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.