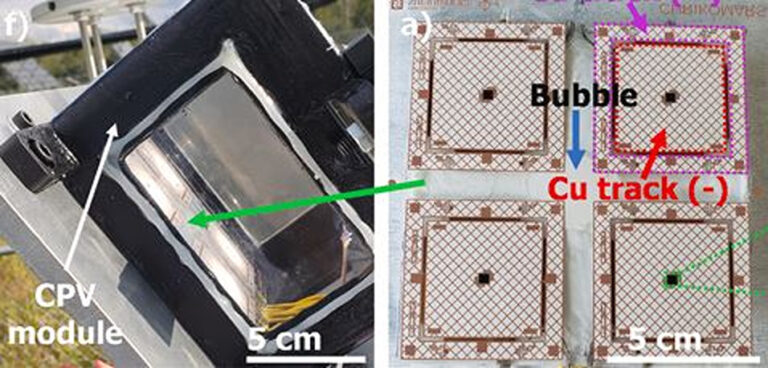

A research group in Canada has optimized the performance of photovoltaic concentrators by using so-called Surface-Mount technology for thermal management. The prototype CPV module uses four non-interconnected III-V germanium cells, a Fresnel lens and a transparent glass circuit board.

Scientists from the Université de Sherbrooke in Canada have fabricated a prototype of a photovoltaic concentrator module (CPV) based on so-called Surface-Mount technology (SMT) – a technique often used to mount electronic components on the surface of a printed circuit board. to assemble. printed circuit board (PCB).

The proposed SMT design did not use wire bonding for cell emitter connection and aims to increase heat dissipation in the CPV panel, which in turn reduces operating temperature and improves performance.

“The SMT, which uses a conductive solder paste for the interconnection, has the advantages of being cheaper and faster for large-scale production, and SMT equipment takes up less space than wire-based wiring equipment,” they explained. “We have developed and applied the SMT process, which integrates the assembly flexibility and improved alignment of solar cells, to assemble solar cells larger than one millimeter.”

The prototype CPV module with 4 solar cells uses a Fresnel lens to focus light on cells soldered to a transparent glass PCB and protected by laminated layers. The emitter contacts are soldered via conductive solder joints to a glass circuit board, in which metal traces for the unsoldered areas are embedded. Transparent underfill fills the gap between the solar cell and the printed circuit board to prevent reflections at the module bottom plate interfaces.

“Bottom filler strips protect the sides of the solar cell to prevent short circuits and contribute to the thermomechanical stability of the assembly,” the research team said. “The back of the assembly is laminated with an EVA encapsulant and a Tedlar protective film to protect the solar cells from the environment.”

Image: Université de Sherbrooke, Solar Energy Materials and Solar Cells, Common License CC BY 4.0

The four cells used in the device are not connected to each other and are triple-junction III-V germanium solar cells, each with an active area of 8.751 mm2. The cost of solar cells based on compounds of III-V element materials, named after the groups of the periodic table to which they belong, has limited the devices to niche applications, such as drones and satellites. These are applications where low weight and high efficiency are more urgent than costs.

The scientists mounted the 4-cell CPV SMT module on a 2-axis solar tracker from the Helios platform at the University of Sherbrooke.

The group performed a series of electrical and temperature measurements on the system under real operating conditions and also performed a series of simulations based on the finite element model (FEM), which is a numerical technique used to perform finite element analysis (FEA) of physical phenomena.

Through their analysis and experiments, the academics discovered that the dimensions of the metal ribbon on the back of each cell and the metal coverage of the PCB are key factors for the thermal management of the CPV module, while the other components have negligible impact. on the module temperature.

“The temperature of the solar cell can be maintained below 80 C over a wide range of dimensions of the metal ribbon behind the solar cell, for both 0% and 100% metal coverage of the PCB,” they further explained. “However, this size range is much larger when the metal coverage ratio is 100% than when the metal coverage ratio on the PCB is 0%.” The simulation also showed that the temperature of the solar cells with a copper ribbon can reach 54 C and with an aluminum ribbon 57 C.

The system was described in the article “Finite element modeling and experimental validation of photovoltaic concentrator modules based on surface-mounted technology,” published in Solar energy materials and solar cells. “These results demonstrate that the use of SMT for the fabrication of CPV modules, in addition to simplifying the assembly process, can improve heat dissipation both through the metal layer on the glass PCB and through the backside contact,” the researchers concluded. researchers. “This opens the door to simpler CPV modules, higher performance CPV modules and higher concentration ratios.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.