Researchers have developed a new passivation process for formamidinium lead iodide perovskite films, which has reportedly resulted in solar cells with an energy conversion efficiency of 23.69% and modules with a certified efficiency of 21.44%. After 1000 hours, the hetero-polytypic passivated devices retained 92% of their initial efficiency and outperformed untreated devices.

An international research team led by the Gwangju Institute of Science and Technology (GIST) in South Korea developed a passivation process for formamidinium lead iodide (FAPbI3) perovskite films, demonstrating it in solar cells with a certified energy conversion efficiency of 23.69%, and modules with 21.44% certified efficiency.

In terms of stability, the hetero-polytypic passivated devices with an additional low-dimensional perovskite (LDP) layer reportedly retained 92% of their initial efficiency after 1000 hours, compared to 63% in an untreated reference device. And the 6H polytype perovskite devices without the LDP retained 81%.

Their work was described in “Shallow defect passivation by 6H perovskite polytype for highly efficient and stable perovskite solar cells”, published by communication about nature.

“A typical approach to date has been to introduce an external chemical reagent to address the defect problem. However, the introduction of external reagents could directly affect the crystalline quality of the perovskite during crystal growth, so our work does not rely on such stabilizers,” said corresponding author Hobeom Kim from Gwangju Institute of Science and Technology (GIST) , South Korea, in a statement. “Instead, we use a chemically identical polytype perovskite, a hexagonal polytype perovskite (6H) that contains a corner-sharing component that effectively suppresses the formation of defects in perovskite.”

To create the component, the team used an excess of lead iodide and methyl ammonium chloride acting on the dominant defect site. Specifically, they inserted 6H into the cubic polytype (3C) of polycrystalline in FAPbI3. The process reportedly improved the structural integrity and carrier dynamics of FAPbI3, resulting in an “ultra-long” carrier lifetime of more than 18 microseconds.

The defect passivation involved the deposition of a surface passivation layer of octylammonium iodide on top of the 3C/6H hetero-polytypic perovskite film to induce the formation of a low-dimensional perovskite (LDP) passivation layer.

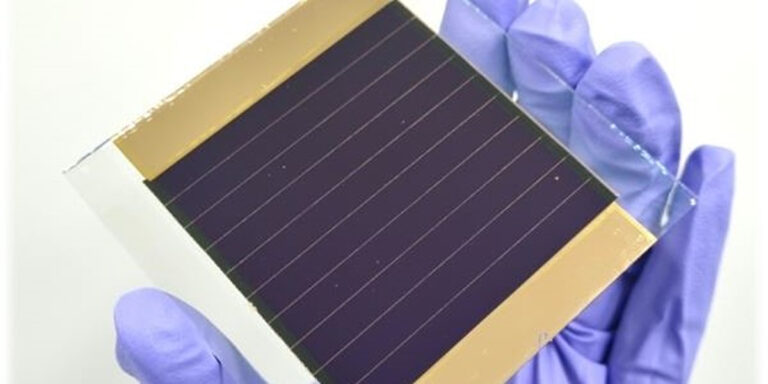

The fabricated cells were made with a pinched structure. They had a fluorine-doped tin oxide substrate, a titanium dioxide electron transport layer, a mesoporous titanium dioxide/potassium chloride layer, a perovskite absorber, a spiro-OMeTAD hole transport layer, and a gold metal contact.

The control device had an efficiency of 20.32%, while the 6H-bridged hetero-polytypic polycrystalline film allowed a device with 22.35%. Further efficiency improvement was achieved via an LDP passivation layer on top of the 6H-bridged perovskite film, resulting in a cell with an efficiency of 24.13%, an open-circuit voltage of 1.156 V and a short-circuit current density of 25.58 mA cm.−2and a fill factor of 81.60%.

The best cell, certified by the Korea Institute of Energy Research, had an efficiency of 23.69%.

The team also fabricated 6.5 cm x 7.0 cm modules in a low-temperature process using eight LDP-passivated 3 C/6H hetero-polytypic perovskite cells with P1, P2 and P3 interconnection. The best performing module was certified by Newport Photovoltaic Testing and Calibration Laboratory with an efficiency of 21.44%.

In addition to the team from South Korea-based GIST, the study also included researchers from the Korea Basic Science Institute (KBSI) and the Korean Research Institute of Chemical Technology (KRICT), along with Japan’s Toin University of Yokohama, Lomonosov Moscow State University in Russia, École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland, and King Abdulaziz University, Saudi Arabia.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.