A team from Jeonbuk National University in South Korea used slot die coating (SDC) to produce uniform, high-quality perovskite films, which they used in a perovskite solar cell that achieved 19.17% efficiency and laboratory cell-sized modules that achieved an efficiency of 17.42%.

A team from Jeonbuk National University in South Korea explored the use of slot die coating (SDC) to create high-quality uniform perovskite films as a step toward large-area production of perovskite devices.

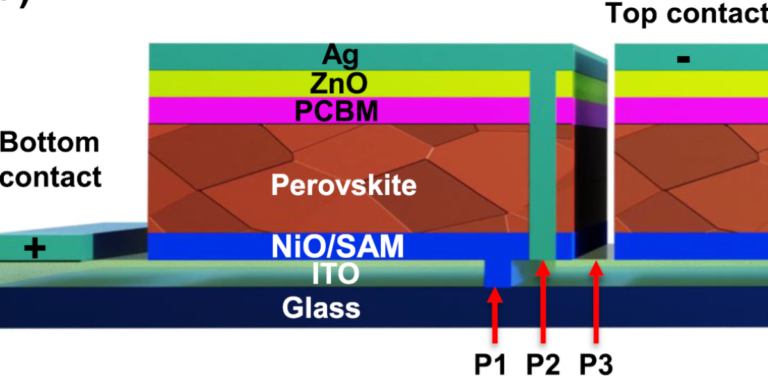

The scientists found that SDC increased the interface roughness of the hole transport layer (HTL), which improved the wettability of the surface, enabling a high-quality perovskite film without bubbles or pinholes. A perovskite solar cell based on the film achieved an efficiency of 19.17% with “excellent” stability results, and a module the size of a laboratory cell achieved an efficiency of 17.42%.

Self-assembled monolayers (SAM), such as Me-4PACz, are excellent materials for the HTL in perovskite solar cells, the researchers noted, but they have poor wettability, which has slowed progress so far. To find a solution, the team analyzed a nickel oxide (NiOX) and Me-4PACz combination. They found that the use of SDC improved the roughness of the HTL interface, resulting in improved wettability.

They explained that the SDC-based NiOx/Me-4PACz hole transport layer suppressed energy losses at the HTL/perovskite interface.

“Applying a simple SDC process to coat NiOX/Me-4PACz HTL enabled the formation of a uniform, high-quality perovskite layer without pinholes, in addition to the SDC-based NiOX/Me-4PACz HTL suppressed energy losses at the HTL/perovskite interface,” the researchers said. “In addition, charge carrier dynamics analysis showed that SDC NiO/SDCMe-4PACz HTL improved the extraction and transport of holes at the perovskite layer interface.”

They also highlighted that the 19.17% efficiency achieved by the device is higher compared to SDC NiO devices which had 15.87%, and said the non-encapsulated devices showed “excellent stability”, achieving more than maintained 85% of their initial efficiency for more than 2,000 hours. a nitrogen atmosphere.

“Our findings suggest that the SDC process not only effectively eliminates the limitations associated with Me-4PACz, but also offers a promising approach for the sustainable mass production of PSCs, which could lead to the fabrication of highly efficient perovskite solar panels and the way free up space for future commercialization,” the team concluded.

The research is described in “Influence of interfacial roughness on slot-die coatings for scaling up high-performance perovskite solar cells”, published by communication materials.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.