A Chinese research group, including scientists from module maker Tongwei, has designed a perovskite solar cell with remarkable perovskite film quality via the so-called self-disintegrating seed strategy. The device not only achieved one of the highest fill factor values ever measured for perovskite solar to date, but also exhibited remarkable stability.

Researchers in China claim to have achieved one of the highest fill factor values for a perovskite solar cell by reducing non-radiative recombination and residual stress through what they called a self-disintegrating seed strategy.

“This strategy achieved a synergistic effect of morphology optimization, interface modification and stress release through functional cations released from seed,” said the study’s lead author Qianyu Liu. pv magazine. “Although the seed in perovskite precursor has been shown to induce perovskite grain growth and increase grain size, previous studies have mainly focused on regulating perovskite crystallization and morphology. However, for perovskite solar cells, the issues of interfacial defects and residual stress in the film are equally critical and challenging to address using conventional seeding strategies.

The scientists attempted to overcome the limitations of the seeding strategy by using a perovskite material known as 2D (4-FBZA).2PbI4, in which a self-disintegrating seed is embedded to improve the crystallization process of the perovskite film. “This material can bind lead iodide (PbI2), which provides large nucleation centers for perovskite grains, improving grain size and crystallinity,” Liu added.

“Through X-ray photoelectron spectroscopy, Kelvin probe force microscopy, density functional theory calculations, and other characterizations, we show that (4-FBZA)2PbI4 decomposes during perovskite grain growth, releasing 4-FBZA+,” Liu further explains. “At the same time, 4-FBZA+ migrates to the interface, passivating defects and stabilizing the perovskite lattice through interactions with FA+ and [PbI6]4-, achieving interface modification of perovskite films.”

According to the research team, the self-disintegrating seed releases damaging tensile stresses in the perovskite film, improving carrier life and promoting hole transport.

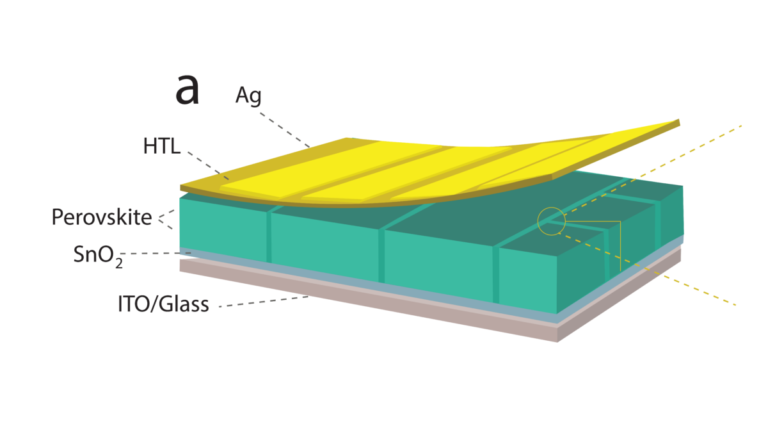

The scientists designed the cell with an indium tin oxide (ITO) substrate, an electron transport layer (ETL) based on tin oxide (SnO2), the perovskite absorber, a hole transport layer (HTL) that relies on Spiro-OMeTAD, and a silver (Ag) metal contact.

Tested under standard lighting conditions, the device achieved an energy conversion efficiency of 23.73%, an open-circuit voltage of 1.133 V, a short-circuit current density of 25.21 mA cm2 and a fill factor of 83.07%. In comparison, a reference device designed without the proposed self-disintegrating seed strategy achieved an efficiency of 22.73%, an open-circuit voltage of 1.117 V, and a short-circuit current density of 24.78 mA cm2.

“Devices manufactured using this strategy exhibit commendable long-term humidity stability, with unencapsulated devices retaining 90% of their original PCE after more than 2,000 hours of aging in air at 60% relative humidity,” explains the research group.

The new solar cell concept was presented in the study “Perovskite solar cells with self-disintegrating seeds deliver a fill factor of 83.64%,” published in Nanoenergy. “This study extends the seed strategy to address interface modification and stress release, addressing the shortcomings of traditional seed approaches and expanding seed research in the field of perovskite solar cells,” Liu said.

The research group included academics from China’s Southwest Petroleum University, Chongqing University, the National Center for Nanoscience and Technology and Chinese solar panel manufacturer Tongwei Solar Co., Ltd.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.