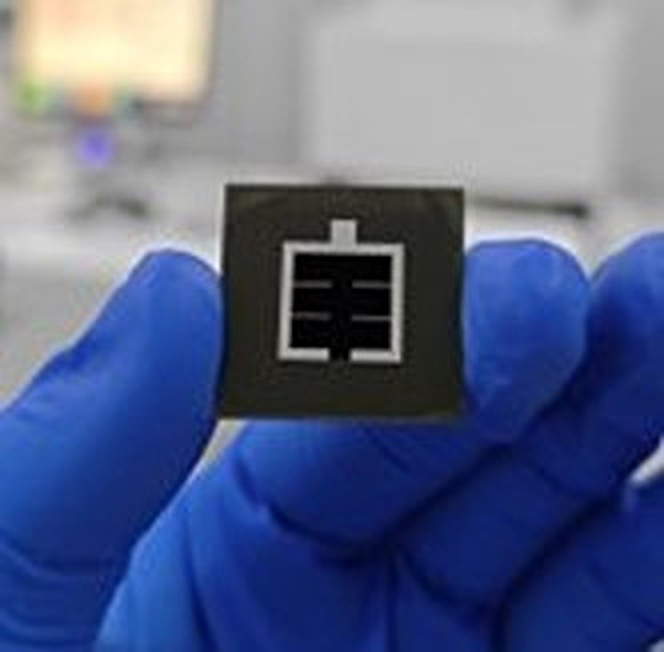

A Saudi-Chinese research team has fabricated a perovskite-silicon tandem solar cell without a hole transport layer (HTL) in the perovskite top cell. This innovative strategy, based on the simultaneous deposition of copper(I) thiocyanate and perovskite in the upper cell absorber, aimed to solve typical problems of HTLs in tandem devices.

An international research team has fabricated a 1 cm2 perovskite-silicon tandem solar cell that uses a top cell based on a perovskite absorber that integrates inorganic solar cells.chief(I) thiocyanate (CuSCN).

“Firstly, a joint deposition strategy of CuSCN and perovskite is developed to solve the key technical challenge: fabricating perovskite top cells on textured silicon bottom cells,” said the study’s corresponding author, Xingbo Yang. pv magazine. “In addition, inorganic CuSCN is also being applied for the first time in perovskite/silicon tandem solar cells and the resulting devices exhibit exceptional light and moisture-heat stabilities.”

The researchers explained that they decided to build the top cell without a hole transport layer (HTL) because HTLs used in top cells for tandem devices usually exhibit defects caused by nonconformal deposition or dehumidification. They deposited the perovskite precursor ink containing CuSCN directly onto the recombination layer made of indium tin oxide (ITO) of a 24.42% efficient heterojunction (SHJ) bottom cell.

“It is confirmed that our approach here forms local hole-collecting contacts through embedded CuSCN in the device, resulting in a different device structure than that of a common and classical pin configuration based on a thin self-assembly monolayer (SAM) on recombination layers such as ITO,” Yang further explained out.

Image: Soochow University

The scientists build the top cell with an ITO substrate, where the contacts are passivated silicon monoxide (poly-SiOX), the CuSCNE-embedded perovskite absorber, a tin oxide (SnO2) layer, a buckminster fullerene (C60) electron transport layer (ETL), and an anti-reflective coating based on magnesium fluoride (MgF2).

In this cell configuration, the CuSCN phase embedded at perovskite grain boundaries acts as both an efficient local hole-collecting contact and a defect passivator. “We verified that CuSCN aggregates at a certain depth at the grain boundaries of the buried perovskite surface, forming local hole-collecting contacts for efficient hole transfer and grain boundary passivation,” the academics pointed out.

Tested under standard lighting conditions, the tandem device achieved an energy conversion efficiency of 31.46%. It was also able to maintain 93.8% of initial efficiency after approximately 1,200 hours of maximum power point tracking at 45 C, and 90.2% after more than 1,000 hours of humid heat testing at 85 C and 85% relative humidity .

“To be commercially valuable, the scale-up of tandem devices has been verified with an opening area of 4 cm2 realized by both spin coating and blade coating, demonstrating a competitive aperture power conversion efficiency of 28.14% and 25.23%, respectively,” Yang added. “It indicates a high scalability and universality of our co-deposition method.”

The device was introduced in the study “Efficient and stable perovskite-silicon tandem solar cells with copper thiocyanate-embedded perovskite on textured silicon”, published in nature photonics. The research team included scientists from Soochow University, Zhejiang University and Hong Kong Polytechnic University in China, as well as King Abdullah University of Science and Technology (KAUST) in Saudi Arabia and Chinese PV production equipment supplier Maxwell Technologies.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content