An Indian-American research team has fabricated a four-terminal perovskite-cadmium telluride tandem solar cell by using a highly conductive and sputtered transparent electrode to increase the current density of the bottom cell. The tandem device combines an 18.3% efficient perovskite cell on top and a 19.53% efficient cadmium telluride bottom unit.

An international research group led by the Indian Institute of Technology Bombay has developed a four-terminal (4T) tandem solar cell based on an upper cell with a perovskite absorber and a lower device made of cadmium telluride (CdTe).

“Perovskite materials have already proven their efficiency and suitability in tandem solar cells, especially in combination with monocrystalline silicon solar cells, as well as CIGS and CIS solar cells,” said one of the lead authors of the study, Ananta Paul, pv magazine. “However, the second most commercially successful CdTe solar cell, after monocrystalline silicon, remains largely unexplored. Given the commercial success of CdTe solar cells, they offer an attractive opportunity for research into thin-film tandem applications.”

The scientists said they adopted an inverted architecture for the top cell design and used a near-infrared (NIR) transparent perovskite absorber with an energy bandgap of 1.63 eV, while a CdTe material with an energy bandgap of 1.39 eV was used. used for the bottom cell.

The key feature of the top device is a highly conductive and sputtered transparent electrode, which the academics say is crucial for the functionality of transparent perovskite solar cells.

“Our team’s distinctive, custom, in-house designed sputtering system with the help of Excel Instruments, Mumbai – India, and a unique thin-film deposition recipe enabled the production of transparent perovskite solar cells with an impressive efficiency of 18.3%,” said the research. author, Dinesh Kabra, said. “This high-efficiency perovskite cell was then coupled with a 19.56% efficient CdTe solar cell, supplied by our collaborator Amit Munshi from Colorado State University in the United States.”

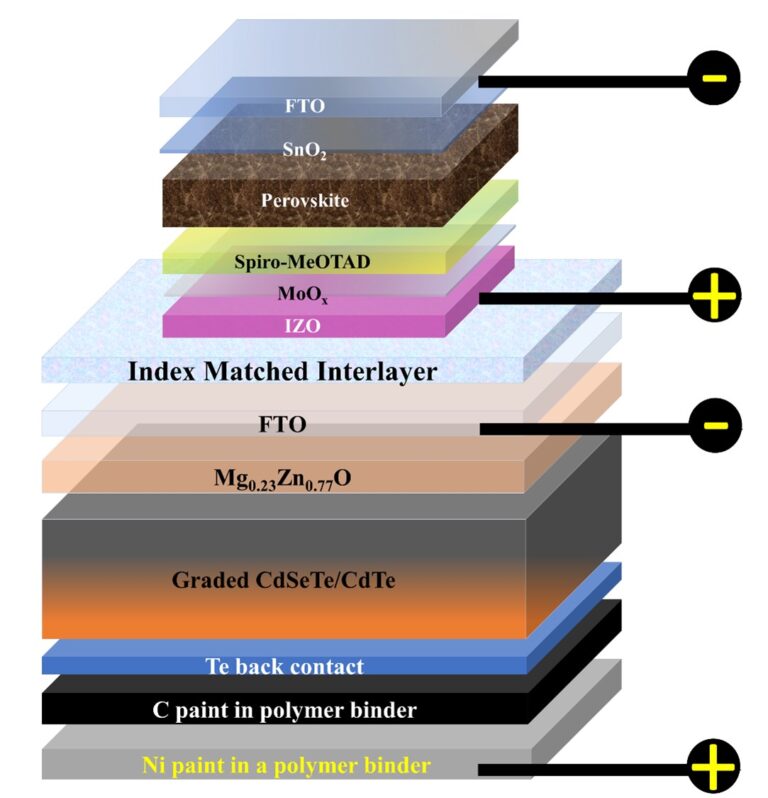

The group designed the top cell with a substrate made of f-doped tin dioxide (FTO), an electron transport layer (ETL) made of tin oxide (SnO2), a perovskite absorber, a hole transport layer (HTL) based on Spiro-OMeTAD, a buffer layer made of molybdenum oxide (MoOx), and a transparent contact based on indium zinc oxide (IZO). Through an index-matched interlayer, this cell was then stacked onto a bottom cell using an FTO substrate, a zinc magnesium oxide (ZnMgO) layer, the CdTe absorber, and a tellurium (Te) back contact.

For the interlayer between the two cells, the researchers used index-matching fluid with a refractive index (RI) of 1.405, which they claim improved the overall current density of the bottom cell.

Tested under standard lighting conditions, the top device achieved an energy conversion efficiency of 18.3%, an open-circuit voltage of 1.07 V and a short-circuit current density of 23.75 mA/cm2and a fill factor of 72.0%. The bottom device achieved an efficiency of 19.56%, an open-circuit voltage of 0.87 V, a short-circuit current density of 27.38 mA/cm2and a fill factor of 82.1%.

The champion tandem solar cell built with the two devices and an active area of 0.175 cm2 achieved an efficiency of 24.2%. A larger device with an active area of 0.805 cm2 achieved an efficiency of 21.13%. It was also found that the cell retains more than 80% of its original efficiency after 3000 hours in dark storage conditions.

The cell concept was introduced in the paper “4-T CdTe/Perovskite thin-film tandem solar cells with efficiency >24%,” published in ACS Energy Letters. “Despite the viability and proven efficiency of CdTe/perovskite thin-film tandem solar cells, they remained uncharted territory,” said co-author Abhijit Singha. “This research will pave the way for a new era in thin-film tandem photovoltaics, and confirm that we can think beyond monocrystalline Si solar cells.”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.