A European research team has attempted for the first time to combine perovskite solar cell technology with textile ceramics in a new building-integrated photovoltaic device. The result is a sunstone with potential for future commercialization, according to its makers.

A research group led by the Universitat Internacional de Catalunya (UIC) in Spain has developed a solar stone based on textile ceramic technology (TCT) and perovskite photovoltaics.

The new device is intended for applications in building-integrated solar photovoltaics (BIPV). “We plan to commercialize this technology,” said the study’s corresponding author, Pedro Casariego pv magazine. “This was the main goal of this research and of a number of parallel projects we are working on.”

TCT was patented in 2011 and consists of a system of ceramic units installed in a grid of steel wires. It was intended for use on deck roofs, grounds and especially facade cladding, but also as a curtain wall that would make ventilation cheap.

“Typically, TCT is used as a dry building system consisting of long shells with a width between 0.6 and 2 meters,” the scientists explained. “One of the advantages of the system is the shorter construction time, as traditional ceramic cladding systems require a manual on-site procedure, where the bricks are placed one by one and connected with mortar. In addition, the large length of the shells makes it possible to cover the ground, facade and roof with the same element.”

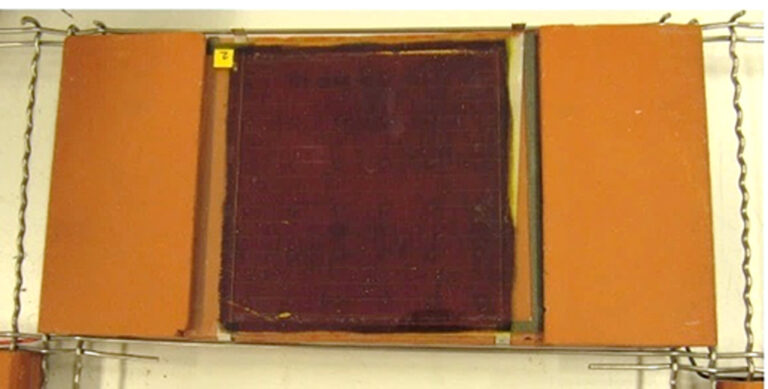

The research group describes the 300mm x 117mm solar brick as a system that integrates a 99mm x 99mm perovskite solar module (PSM) compatible with TCT mesh. Welding was used to make the electrical connections for the module, which was embedded in a groove with an inclined geometry.

Stainless steel plates with a double L shape were also used to achieve a dry bond between PSM and the ceramic pieces. “It should be pointed out that the groove is not always made in the center of the ceramic piece and can be made further to the right or left to allow different possibilities and play a little with the composition,” the academics explained.

“The sunstone has been designed from the ground up and has achieved a Technology Readiness Level (TRL) of 5,” said Casariego. “The perovskite module has been individually tested in real environments and the solar stone has undergone impact, vibration and thermal shock tests.”

The tests showed that the PSM is hardly affected by a hard impact, although the groove made in the ceramic piece to harden the PSM reduces the strength of the bricks.

“In the event of a hail impact, a reduction in efficiency is observed, although the cell continues to operate,” the scientists noted. “Some vulnerability of the electric welding is observed during vibration tests. One of the failures occurred when testing at 10 Hz.”

Through voltage measurements, the scientists also discovered that the PSM is not affected by the vibrations. “Overall, the SB was not affected by the imposed vibration loads during the tests,” she added. “The designed dry connection between the ceramic piece and the PSM works adequately.”

Overall, the sunstone was found to perform well “in general terms” in terms of market viability, with the main challenge identified in the brittle fracture of the ceramic pieces. “Future research should include a revision of the sunstone design,” the academics concluded.

The new technology was presented in the study “Perovskite solar stone design for textile ceramic technology”, which was recently published in Construction and building materials. The research team included scientists from the University of Rome Tor Vergata in Italy and the French Commission for Alternative Energy and Atomic Energy (CEA).

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.

Popular content