Researchers in Singapore used a biomass derived polymer to increase the efficiency of hybrid organic inorganic perovskiet solar cell. The cell also appeared to obtain an efficiency trait of 90% even after 1,100 hours, which compared to 52% for benchmark cells that have been designed without the proposed polymer.

Researchers from Nanyang Technological University, Singapore, have developed a new biomass-derived polymer for hybrid organic-an organic perovskite solar cells (HPSC). It is said that it improved both efficiency and stability compared to reference devices.

The PBDF-DFC material is also claimed that it makes it possible to potentially simpler manufacturing processes.

“The research is inspired by two important challenges in the current perovskite solar cells: environmental problems about polymers derived from petroleum that are currently used as photoactive layers and complex manufacturing processes as a result of polymer solubility restrictions of existing conjugated polymen,” corresponding author, leonard ng, leonard ng, told PV -Magazine.

The scientists were looking for an alternative to conjugated polymers based on petroleum -based thiophene, which require precursors of solvents and are reportedly more complicated to manufacture.

Furan is extracted from agricultural waste and contains chalcogen aromatic connections, the team noted. The PBDF-DFC polymers based on that are very soluble in Perovskiet-Voorlopersplosids, which makes a simplified manufacturing method for direct front buyers possible.

“The PBDF DFC shows a high solubility compared to sitting forerunner solutions, which makes direct inclusion in the precursor solution possible,” the researchers said. This “considerable” streamlines the manufacturing process, which reduces steps and the production costs may be reduced.

“The Biggest Challenge was working with furan-based polymers, which had Been Underexplored in perovskite solar cells despite their potential benefits,” Said ng Wei Tat, explaining that the team had to develop new furan synthesis to overcome lower yieldsis 70% compared to traditional thiophene -based synthesis. “We also had to explore new ways to integrate the Furan -based polymers directly into the device pile.”

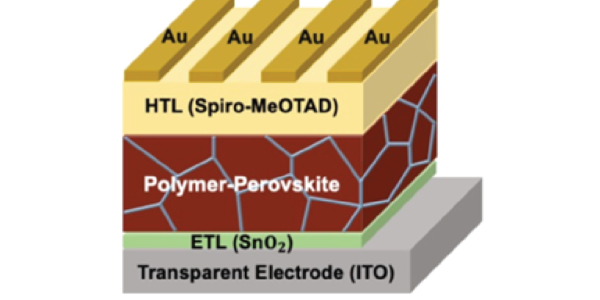

To test their new material, the researchers investigated a hex-soluble fraction that they have labeled FP1-H and an inchloroform soluble fraction, with the FP1-C label. The FP1-H was used by the team in an HPSC based on a stack as follows: IndiumTin-Tinoxide (ITO) Glass, Tin (IV) Oxide (SNO2) Electron Transport Layer (ETL), Perovskite-FP1-H, Spiro-Opad -Low and silver (au) electrode contacts.

The operating device of the experiment had a maximum efficiency of 19.84% with a short -circuit current density of 22.81 mA cm – 2, an open circuit voltage of 1.10 V and a filling factor of 75.88%. The HPSC champion had a maximum efficiency of 21.39% with a short-circuit current density of 24.17 MA CM-2, an open circuit voltage of 1.08 V and a filling factor of 76.60%.

With the help of X-ray fraction, scanning electron microscopy and transmission-electron microscopy to analyze samples, the team noted that “the PBDF DFC accumulates on grain boundaries, the improvement of film crystallization and reducing defects.” It emphasized that the “double innovation of a new polymer and simplified manufacturing process” offers an opportunity to make HPSCs more efficient, more stable and possibly more sustainable.

“The successful integration of PBDF-DFC and the Direct Precursor Integration method opens new roads for streamlined production of powerful perovskite solar cells, which tackle important challenges in scalability and environmental impact,” concluded the Academici.

Their work is described in “Direct integration of Furan Polymers derived from biomass for improved stability and efficiency in hybrid perovskiet solar cells“Published in Advanced functional materials.

In view of the potential for HPSC performance improvement, NG said: “Future work will focus on optimizing device stability through innovative changes in device architecture, while scalable production processes are explored.”

It includes work on new device stack configurations, interface engineering approaches and alternative electrons and hole transport layers.

“An important priority is to adjust their direct precursor integration method for industrial scale production, in particular exploring printable photovoltaic systems using inkjet, screen and roll-to-roll printing techniques” Different environmental conditions is also planned.

Other materials derived from biomass can further improve performance and sustainability, according to NG Wei Tat. “The solution processability of the Furan-based polymer also opens opportunities for developing flexible and lightweight perovskite solar cells, making new device architectures possible that were not feasible with traditional polymers based on petroleum,” he concluded.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.