Optimization of thermal stability in solid oxide fuel cells

Solid oxide fuel cells (SOFCs) represent a highly efficient and clean energy conversion technology, converting chemical energy directly into electrical energy through electrochemical reactions. These cells are increasingly used for distributed and stationary energy generation. However, practical application requires taking into account user actions and maintenance, which often exposes the device to significant temperature fluctuations. In residential environments, SOFC systems often switch on and off based on the homeowner’s needs.

SOFCs can experience temperature changes during operation, especially when generating electricity from waste heat in industrial processes or thermal power plants, where the heat supply is inconsistent. In addition, environmental factors such as daily temperature fluctuations and extreme weather conditions can lead to significant thermal fluctuations. These temperature variations cause thermal stresses due to the mismatch in the coefficients of thermal expansion (TEC) of different SOFC components, potentially degrading the interfaces and reducing the output power. Therefore, maintaining thermal cycle stability is critical for the commercialization of SOFC technology.

A recent study by a team of materials scientists, led by Liangzhu Zhu of the Key Laboratory of Advanced Fuel Cells and Electrolyzers Technology of Zhejiang Province, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, China, proposed a new approach. They synthesized single perovskite oxide-decorated RP-structured oxide using a self-assembly method to improve catalytic activity and stability. This work demonstrated an excellent TEC match between strontium lanthanum ferrate and the electrolyte, demonstrating its potential as a competitive air electrode for SOFCs.

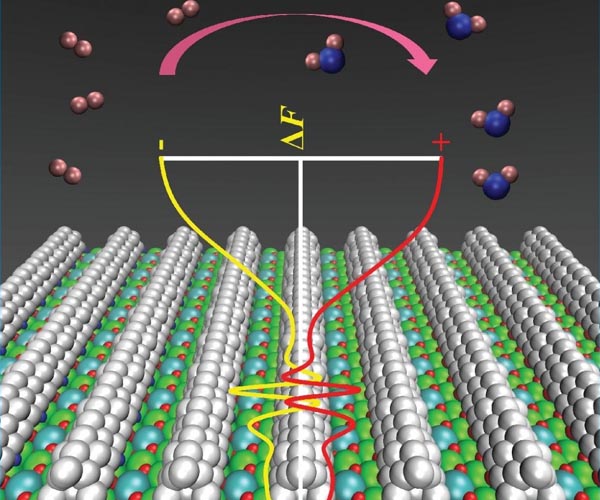

“In this report, we synthesized two-phase La0.8Sr1.2FeO4+d and La0.4Sr0.6FeO3-d by the simple self-assembly method. The single perovskite oxide, La0.4Sr0.6FeO3-d (LSF-P), with cubic structure and high catalytic activity, was introduced to facilitate charge transport through the RP-structured oxides La0.8Sr1.2FeO4+d (LSF-RP) with different orientations. This approach overcomes the anisotropy inherent in the structure and at the same time improves the catalytic activity of the composite electrode. The intimate hetero-interfaces that can form in situ between LSF-RP and LSF-P particles are expected to accelerate the charge transfer process, thus improving the ORR kinetics double phase on the phase structure, thermal expansion coefficient, electrode reaction kinetics, performance of a single cell under thermal cycling and reversible conditions in detail The results obtained indicate in detail that the incorporation of LSF-P improves the oxygen surface exchange kinetics, reduces the polarization resistance and. significantly improves the performance of a single cell without sacrificing the stability of the composite electrode,” said Liangzhu Zhu, professor at Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, China.

“The TEC values of RP oxides are comparable to those of the electrolytes commonly used in SOFCs. However, it is important to note that RP oxides exhibit two-dimensional conduction. They exhibit significant anisotropy in the diffusion of oxygen ions and electrons, with transport mainly occurring in the ab plane and minimal movement along the c axis Therefore, there is a need to modify the RP structured material to improve their charge transfer ability, thereby increasing their catalytic activity, without affecting it. at the expense of stability for application in SOFCs.

Introducing a secondary phase is a common strategy to stimulate the catalytic activity of RP oxides. “Mechanical mixing is a relatively simple method for the introduction of a secondary phase. Although mechanical mixing can improve electrode performance to some extent, it struggles to achieve a homogeneous distribution of the phases, which in turn affects the interfacial contact limited between them. Infiltration is another alternative to the introduction of second-stage material. However, it is a cumbersome and time-consuming process that requires multi-step operations,” said Yang Zhang, one of the co-first authors and a postdoctoral researcher. at Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, China.

“The self-assembly synthesis technique for manufacturing composite materials is capable of yielding thermodynamically stable and homogeneously dispersed two-phase structures in a single, streamlined operation. By merely adjusting the proportions of the starting materials, the incorporation of the second phase can be accurately are carried out.” Furthermore, this self-assembly approach holds great promise for creating numerous heterogeneous structural interfaces within composite air electrodes, which in turn can significantly improve the kinetics of oxygen reduction reaction (ORR) and the performance of composite air electrodes by optimizing the ORR process,” says Liangzhu Zhu.