NREL’s laser technology simplifies the recycling of solar panels

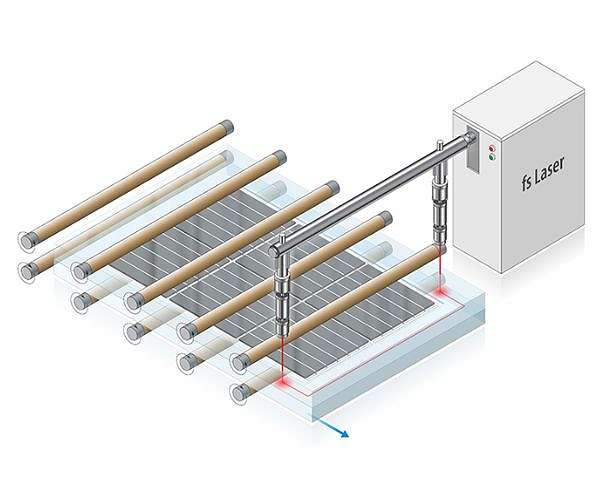

Researchers at the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) have developed a new method using femtosecond lasers to create glass-to-glass welds in solar panels, significantly simplifying the recycling process. This innovation replaces the traditional use of plastic polymer sheets, which complicates recycling efforts.

By eliminating polymers and using laser welding, the solar panels can fail at the end of their life, making glass and metal components easy to recycle and silicon reused. David Young, senior scientist and group manager at NREL, emphasized that polymers are a major obstacle in current recycling processes. “Most recyclers will confirm that the polymers are the main problem when it comes to inhibiting the recycling process,” Young said.

The study, “Towards Polymer-Free, Femto-Second Laser-Welded Glass/Glass Solar Modules,” co-authored by NREL’s Tim Silverman, Nicholas Irvin and Nick Bosco, along with Trumpf Inc., introduces a strong, hermetic seal formed by the laser welding that is applicable to various solar technologies, including silicon, perovskites and cadmium telluride.

NREL’s findings, as Young detailed, prove that the laser welds are robust: “As long as the glass doesn’t break, the weld won’t break.” He added that the modules without polymers need to be stiffer, a challenge addressed by adjusting the relief characteristics of the glass to withstand static load tests.

The research not only improves the sustainability of the modules, but is also in line with the objectives of extending their operational life to more than 50 years and simplifying recycling procedures. This innovation represents a significant advancement in solar technology, potentially reshaping module construction and end-of-life processing.

Research report:Towards polymer-free, Femto-Second laser-welded glass/glass solar modules