The French cable manufacturer unveiled new low-carbon products for large-scale PV projects.

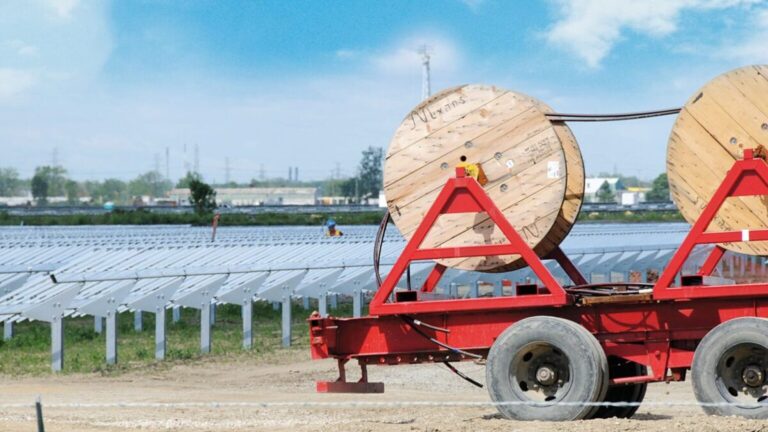

French cable manufacturer Nexans has launched a low-carbon product for large-scale PV projects.

Cables are often seen as a commodity, only considered at the end of a project. However, Nexans argues that they are precisely one of the elements that can influence the economic profitability and CO2 impact of a photovoltaic project, especially in France, where strict carbon footprint rules apply to utility-scale PV tenders.

“In general, the developer adjusts its cable based on the peak load of its photovoltaic installation, which is often higher than the actual needs, resulting in additional costs,” says Elyette Roux, Managing Director of Nexans and Vice President of the Global Business Unit Leading energy transition, told pv magazine France.

“Depending on the characteristics of the connection such as soil type, solar panels, presence or absence of storage, or distance to the source station, we have a number of standardized elements that we have acquired with experience and that allow us to propose to our customers different optimized scaling scenarios, depending on the levels of risk they are willing to accept.”

The manufacturer also said that the CO2 impact of its products meets the corporate social responsibility (CSR) requirements of customers willing to have their solar farms certified with the PEP Ecopassport, which measures the environmental impact of electrical products and climate technology in France certifies.

According to the company, the production of one kilometer of electricity cable currently generates an amount of CO2 that represents two to three times the average annual emissions per capita in France. These emissions mainly come from the aluminum conductor, which alone represents between 70% and 90% of the total footprint, followed by plastics, transport and the manufacturing process.

That’s why Nexans has been offering underground and above-ground HTA and LV cables since 2023 that guarantee a minimum greenhouse gas emissions reduction of 35% compared to standard cables. To achieve this, 100% low-carbon aluminum is used, produced with 100% low-carbon energy, and 10 to 50% recycled plastics in the insulation and/or sheathing.

The low-carbon cables are produced at the factories in Jeumont and Bourg-en-Bresse, which benefited from a €15 million ($16.4 million) investment last August. To increase its source of cables for recycling, Nexans also optimized the sorting of aluminum waste at its production sites in Europe through Recycâbles, a joint venture between Nexans and Suez, with the aim of reintegrating them into electrical cable production.

At the same time, the company also established a buyback circuit for all types of end-of-life cables, whether copper or aluminum, from its customers and partners.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.