Researchers from the Vidyasirimedhi Institute of Science and Technology from Thailand showed a new hydrogel that has a high cooling effect on Silicon PV panels. The lightweight technology reportedly makes a temperature drop of 23 ° C possible, from 70 to 47 ° C, and a relative increase of 12.3% power conversion efficiency.

Researchers from the Vidyasirimedhi Institute of Science and Technology (Vistec) in Thailand have shown a passive cooling material to tackle heat-related Silicon PV output losses.

“We produced a passive cooling System Requiring Significantly Less Material But Producing Very High Cooling Capacity and Cooling Power Compared With The Benchmarks. Our Hydrogel Design has a Thermoresponsive Polymer As the Main Network, Interlaced withhay,” Pattanasattayavong, Corresponding Author of the Research, Told PV Magazine.

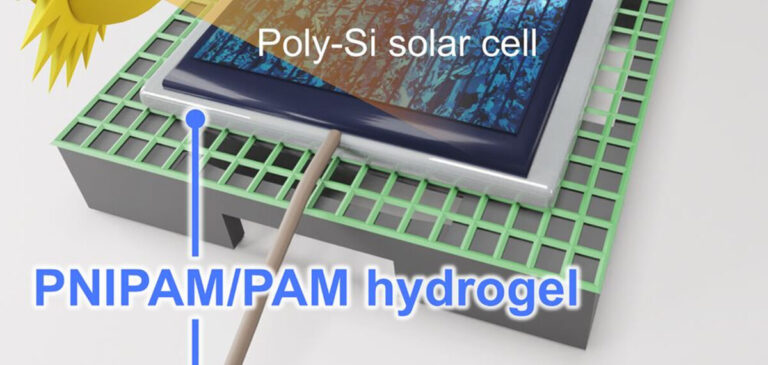

The Hydrogel is described as thermoresponsive poly (N-Isopropylacrylamide) (Pnipam) Semi-interpenetring polymer networks (Semi-IPNs) that contain poly (pva), poly (ethyleneglycol) or polyacryylamide.

“It is crucial that the required weight for us optimized system, the 15 wage% pnipam/pam semi-ipn hydrogel, was only 5.14 kg m2, which is 80% -85% lower compared to other examples,” said the researchers who have the point that the lower weight) cools.

The hydrogels were applied to the back of metal sheets mounted at 4.8 cm x 6.0 cm PV supplied by the British kitronik. Three setups were tested: a pnipam/pam -monster of 15 gain.

The volume of the hydrogels was raised to match the dimensions of the solar cells and the higher temperatures that were reached during the heating period. The measurements of water reduction ratio and differential thermal analysis (DTA) showed that the “cooling performance of Hydrogels not only depends on how much water they absorb, but also on how quickly they can release water,” the scientists said.

The specific cooling capacity (SCP), which is noticed as WG – 1, was 1.86 Wg – 1. They added that by taking Pam in the Thermoresponsive Pnipam hydrogels to realize Pnipam/PAM Semi -In -interpenetring polymer network hydrogels, a large swelling ratio of 30 was. The optimum pnipam/pam -hydrogels also showed a high water delivery ratio (WR), so that 80% of the absorbed water was driven out within 10 minutes. The optimum composition of pnipam/pam hydrogels with 15 gain% PAM turned out to have the largest swelling ratio of 30 and the highest SCP of 1.86 Wg – 1.

The hydrogeling system reportedly made a temperature drop of 23 ° C possible, from 70 to 47 ° C, and a relative increase of 12.3% power conversion (PCE) compared to the reference device. “The most surprising thing was to see the drastic change in the temperature of PV sun cells after our material applied. It is remarkable that 90% less material is required to achieve less than 20 ° C temperature reduction and more than 12% increase in efficiency,” said Pattanasattayavong, a temperature of the ° Caphabes, the congratulations of the weakness of the wake -up material of the wake -up material of the wake -up material of the weakness of ° Chartiekials, the weakness of ° Chartiekials, the weakness. 0.9% and a relatively 7.4% increase.

Their findings are available in “A lightweight hydrogeling system for passive cooling of solar cells“Recently published in Advanced Materials Technologies.

“We have received very positive feedback from our industrial partners who are interested in upgrading the technological readiness level of our findings for practical commitment,” said Pattanasattayavong. “On the one hand, we want to better understand the relationship between the material structure, cooling speed and cooling force. On the other hand, we are working on designing an efficient, practical process to produce and apply a layer of our material on the back of PV cells.”

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.