Researchers in China and Malaysia simulated a new structure for copper-zinc tin sulfide (CZTS) cells with a tungsten oxide buffer layer and a field kesterite layer on the back surface. A device simulated with this configuration achieved an open-circuit voltage of 1.2 V and a fill factor of 83.37%.

A group of researchers from China and Malaysia have proposed a new structure for copper-zinc tin sulfide (CZTS) thin-film solar cells in an effort to improve efficiency and use more environmentally friendly materials.

The team chose tungsten oxide (WO3) as the buffer layer based on the properties and performance revealed in previous research, such as its high band gap and “excellent electrical conductivity.” It was used to replace the cadmium sulfide (CdS) buffer layer, which the team said is toxic and comes at a high cost. In addition, the team chose to apply a back surface field (BSF) based on Cu2ZnSnSe4 (CZTSe) between the absorber layer and the metal substrate Platinum (Pt).

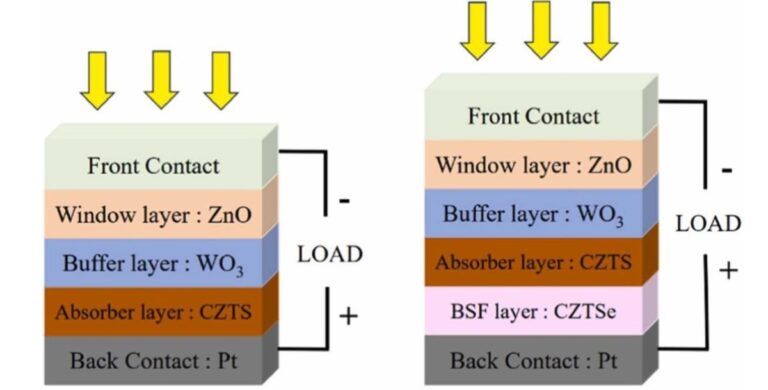

In the study, one device was structured without the BSF layer, with zinc oxide (ZnO) as window layer, WO3 as buffer layer, CZTS as absorber layer and Pt metal substrate, noted by the researchers as Pt/CZTS/ WO3/ZnO structure. The other device was structured similarly, but with an additional CZTSe BSF layer sandwiched between the CZTS and Pt layers, which was noted as Pt/CZTSe/CZTS/WO3/ZnO structure.

The group then analyzed the structures with and without the BSF layer. It investigated how layer thickness, operating temperature, back contact layers, acceptors and defects in the BSF layer affected performance using SCAPS-1D solar cell capacitance software developed by the University of Ghent.

Comparison between the two structures showed that the addition of the BSF layer could increase the performance of the CZTS solar cell. The best results of the Pt/CZTSe/CZTS/WO3/ZnO device indicated an open-circuit voltage of 1.2 V, a fill factor of 83.37%, and an energy conversion efficiency of 29.3%. This was an improved result compared to the solar cell without BSF layer, which had an efficiency of 23.01% according to the team.

In their closing remarks, the scientists said that in industrial practices it is necessary to consider material costs, environmental sustainability and material defect density to achieve large-scale production. “Future research should focus on advancing the development and stability of multi-heterojunction solar cells, investigating metal ion doping and improving thin-film techniques,” they said, claiming that this research should provide a new way to improve the performance of similarly structured solar cells. solar cells to enable the industrialization of cheap and highly efficient PV cells.

The research is documented in “Efficiency improvement of CZTS solar cell with WO3 buffer layer using CZTSe BSF layer”, published in Energy reports. The research team included scientists from China-based Wuhan University, Malysia-based Multimedia University and Xiamen University Malaysia.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.