The system was devised by scientists in Japan and consists of a xenon flash lighting system and a detector capacitor. It could reportedly examine solar panels and find the faulty modules without disconnecting the electrical wiring from the string.

Researchers from Japan’s Ibaraki University and Shiga Prefecture University have developed a new PV module deterioration diagnosis device that can reportedly inspect an array of cells and spot the deterioration in each individual module without disturbing the array’s electrical wiring to disconnect.

“Detection of deterioration of individual PV modules can minimize the number of PV modules that need to be replaced and enable economically beneficial long-term operation of commercial PV power plants,” the academics said. “In addition, it also contributes to the reduction of PV module waste and effective use of resources.”

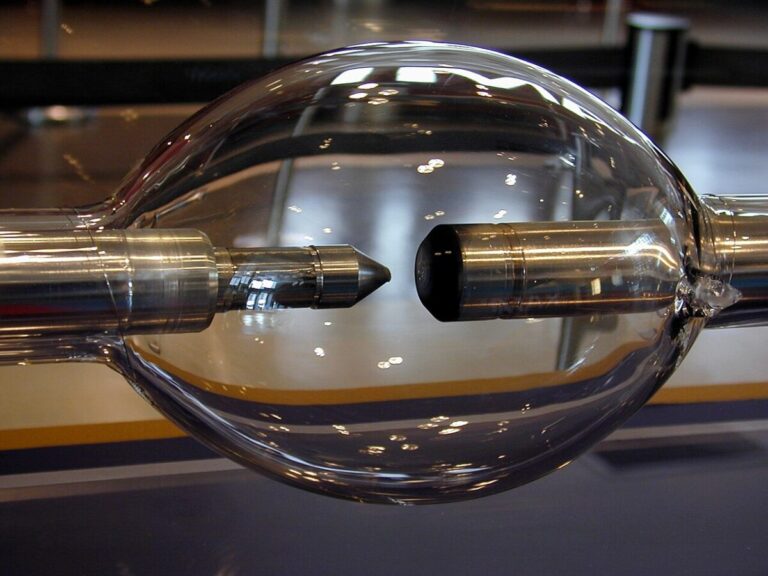

The new solution uses a Xenon flash illumination system to irradiate flash light onto a target module, which is connected to a detector capacitor. The measured charge voltage value of the detector capacitor is used as the decision index voltage for the presence of deterioration.

“When only two or three PV modules are connected in series in a solar cell array, the decision index voltage is sufficiently high and almost the same as in the case of a single, separated PV module,” the team explains. “Unfortunately, however, it was found that the decision index voltage generally decreases as the number of PV modules connected in series increases. This voltage reduction makes accurate deterioration diagnosis of individual PV modules difficult because the difference between the decision index voltages in the cases of non-deteriorated and degraded PV modules becomes small.”

To solve this problem, the academics added a unique auxiliary diode network to the device. This network consists of many diodes and allows the isolation of a single device without disconnecting it, so that the measured current comes only from the relevant module. “This connection can be easily completed in the solar cell string junction box by running preliminary electrical wiring from the output terminal of each PV module in the solar cell string to the junction box,” they pointed out.

Before building an experimental setup of the system, the team simulated it numerically using the PSIM software. “From the simulation calculations with the inserted auxiliary diode network, it became clear that generally high decision index voltages are obtained and that the voltages for different deterioration conditions can be clearly distinguished from each other,” it further explains. “In contrast, the decision index voltages obtained for the simulation model without the inserted auxiliary diode network generally decrease by comparison.”

After the positive results of the simulation, the scientist created a prototype of an experimental setup. It included eight PV modules with a rated output power of 30 W, connected in a string and a ceramic resistor set to 0.5 Ω, attached to one of them to simulate a 5% degradation. In addition, the setup included a detector capacitor, a synchronous switch for the lighting period, a reset switch, a reset resistor and an auxiliary diode network.

“The detection tests were conducted for the case where a 5% degraded PV module was mixed with the other non-degraded PV modules,” the scientists said. “It was revealed that the obtained decision index voltage only decreases when the 5% degraded PV module is inspected by selecting it as the diagnosis target, and the 5% degraded PV module can be clearly distinguished from the other non-degraded PV modules by the significant voltage difference compared to normal.”

The new device was presented in “New device for diagnosing deterioration of individual photovoltaic modules, usable without disconnecting the electrical wiring in the solar cell array”, published in the field of renewable energy.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.