An international research team has manufactured a perovskite solar cell using sulfur-based additives to improve its resistance to moisture. The device not only achieved high efficiency levels, but was also able to maintain approximately 96% of its efficiency after 1000 hours.

One of the key challenges for the scientific community and the PV industry to commercially produce perovskite solar cells (PSCs) is the need to improve moisture stability. Protecting the perovskite layer from moisture is essential to prevent excess water from forming on the layer itself, as this can damage the crystallinity of the cell structure, affecting overall performance.

An international group led by the Basque Center for Materials, Applications and Nanostructures has in Spain developed one moisture-resistant perovskite solar cell using sulfur-based additives. “Tuning the iodide and bromide tails of additives reveals the influence of sulfur heteroatoms containing ammonium salts on the photophysical and device properties of a formamidinium-rich perovskite absorber,” says the corresponding author of the study. Shahzada Ahmad, narrated pv magazine. “By applying this additivization strategy, we examined the obtained stability with proton migration analysis and Kelvin probe microscopy under humidity.”

In particular, the scientists used a type of commonly used ammonium additives, which underwent a deprotonation reaction to form volatile amines and halogens, which they believed would negate the passivation effects during long-term cell function. “Using resonance stabilized amidinium counterparts was our strategy,” Ahmad said. We have proposed for the first time a rational additivization strategy to increase the long-term water and moisture stability of the pure formamidinium lead triiodide (FAPbI3) layer by multifunctional organic salt containing ammonium and amidinium termini, and oxygen-assisted water uptake on the perovskite surface.”

According to the researchers, the induced lead sulfide (Pb-S) interaction and the engineered crystallization growth were responsible for the improved stability of the cell. “Moisture-assisted perovskite degradation mechanisms were investigated, including surface adsorption of water molecules, proton migration with perovskite ammonium ends, and oxygen-assisted water uptake on the perovskite surface,” Ahmad continued.

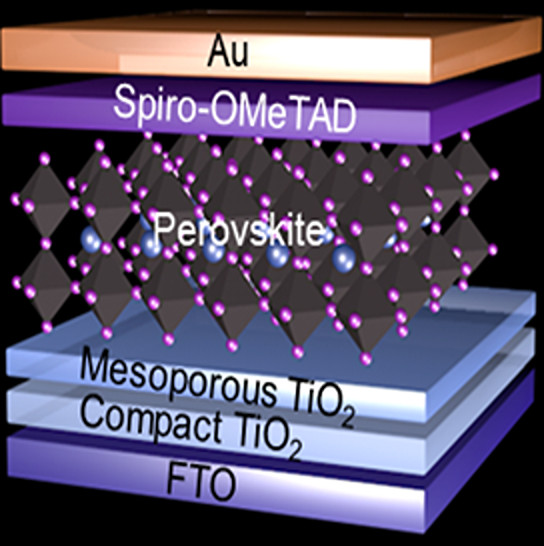

The research team built the cell with a fluorine-doped tin oxide (FTO) front electrode, compact and mesoporous titanium dioxide (c-TiO2 and m-TiO2, respectively), the perovskite absorber, a spiro-OMeTAD hole-blocking layer, and a gold (Au) metal contact.

The champion solar cell developed with this structure achieved an energy conversion efficiency of 25.1%, an open-circuit voltage of 1,165 mV, a short-circuit current of 25.88 mA cm–2 and a fill factor of 83%. A reference cell built without sulfur-based additives achieved an efficiency of 22.49%, an open-circuit voltage of 1,115 mV, a short-circuit current density of 25.16 mA/cm2 and a fill factor of 80%.

“The additives demonstrably contribute to strengthening the crystal lattice of the perovskite grains, reducing their tendency to undergo irreversible conversion to lead(II) iodide (PbI2),” the research group explained, noting that the cell was also able to maintain approximately 99.6% of its original efficiency after 1,000 hours.

“Our developed methodology with heteroatomic additivization strategy not only achieves high intrinsic stability for formamidinium-enriched thin films, but also increases the device performance from 22.49% to 25.14%,” the academics concluded.

The device was described in “Uncovering the Nanoscopic Moisture Ingress in Multifunctional Added Halide Perovskites”, published in Advanced energy materials. The team also included scientists from Huazhong University of Science and Technology in China, the University of Bordeaux in France, and the Max Planck Institute for Polymer Research in Germany.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.