US researchers at the Department of Energy’s National Renewable Energy Laboratory used a circular economy framework to determine how metal halide perovskite solar panels can be scaled, deployed and designed to be easily recyclable in the future.

Researchers at the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) used a circular economy framework to determine how future metal halide perovskite solar panels can be scaled, deployed and designed so they are easily recyclable.

While initiatives are underway to commercialize metal halide perovskite (MHP) solar technology, particularly efforts to ensure sustainable performance in the field, NREL researchers have initiated a study of sustainability design factors as another important aspect of commercialization.

“Our goal with this perspective document was to point out that existing technology does not prioritize building products with sustainability and circularity top of mind. It is not specifically designed to minimize waste or use the lowest energy processing steps,” said Joey Luther, the study’s corresponding author. pv magazine. “However, since PV is inherently a sustainable technology, now is the time to begin evaluating how we can develop the commercialization of MHPs with sustainability in mind.”

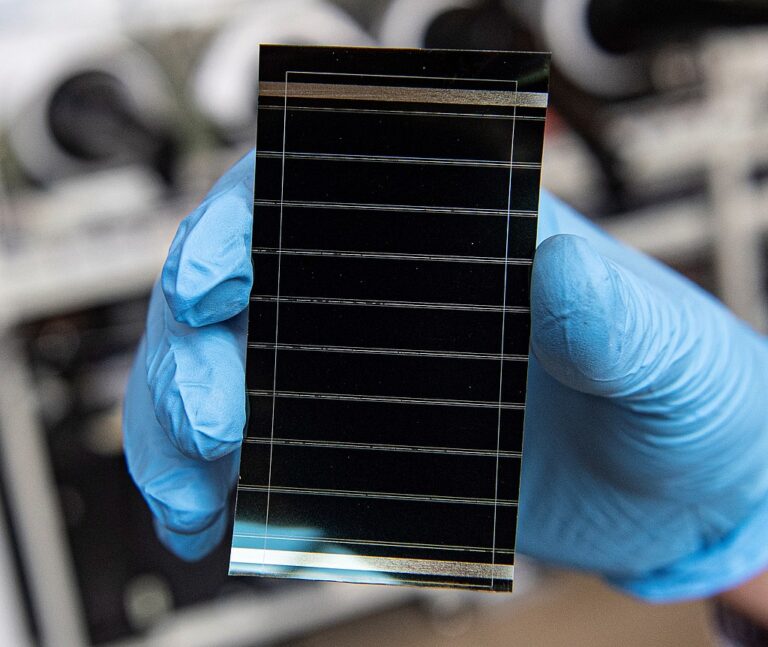

The group conducted the evaluation based on a prototypical single-junction MHP module close to commercial designs, framed with mounting rails in a glass-glass module configuration with polymer encapsulants, and edge sealing typical of silicon and cadmium telluride panels. The individual PV cells are integrated via inscriptions and include front glass coated with a transparent conductor, the MHP layer sandwiched between electron and hole transport materials, and a back electrode.

In addition, the team delved into the constituent chemicals, molecules and materials typically used at perovskite A, B and X sites.

For all of the above, sustainability aspects were evaluated, such as energy intensity of production, carbon intensity, rare mineral mining, recyclability, resource abundance, cost, fossil fuel derivatives, fail-safe encapsulation, health hazards and flammability.

The prototype was further evaluated based on critical material issues, embodied energy, carbon impact and circular supply chain processes. The analysis included the frame, rail materials, front and back glass, encapsulation polymers, solvents, electron and hole transport materials, and electrode materials.

In an information-rich table, the team has described in detail how the eleven ‘R’s’ of circularity for solar photovoltaics can provide opportunities and benefits within sustainable production. An adaptation of the concept of ‘reduce, reuse, recycle’. Some of the R’s discussed are listed here: reject fossil fuels and carbon-intensive materials; reducing energy, material and carbon input, repair or design for repair, reuse, repowering, restoration and energy recovery.

When it comes to recycling, the researchers noted that “recycling” includes both the downcycling of lower value or lower quality products. They explained that recycling is beneficial when recovered raw materials replace new materials, which require energy-intensive refining. There is room for improvement. For example, PV glass production continues to use virgin sources in new PV glass products and not post-consumer PV glass waste, they noted.

The team identified five key areas and opportunities to pursue. The first is to improve the reliability of MHP modules to meet current commercial PV lifespan standards. Second, examine the supply chain of low-trade volume raw materials, such as cesium, and ensure sufficient accessibility for the sustainable scale-up of a particular MHP compound, or focus on research to reduce or replace it. Third, look for alternatives to indium. Fourth, explore how to accelerate PV glass recycling without downcycling. And fifth: further improving module remanufacturing processes.

“A reasonable combination of these solutions would enable MHP-PVs to make a meaningful and sustainable contribution to the energy transition,” the team emphasizes.

The scientists claimed that “making the PV supply chain circular, especially through glass recycling and remanufacturing,” offers opportunities to reduce the embodied energy and carbon of MHP PVs. “Improvements in longevity and reliability remain critical to the energy transition and provide the greatest benefits,” they concluded.

The perspective is detailed in “Sustainability pathways for perovskite photovoltaics”, published by natural materials.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.