Scientists in India have proposed using thermoelectric cooling to improve the performance of PV modules. Through a field experiment, they discovered that thermoelectric coolers in combination with water can reduce the temperature of solar panels by up to 38 degrees Celsius.

Researchers from India’s Shoolini University conducted a field experiment to analyze the effect of thermoelectric coolers (TECs) and water cooling on the temperature of PV modules.

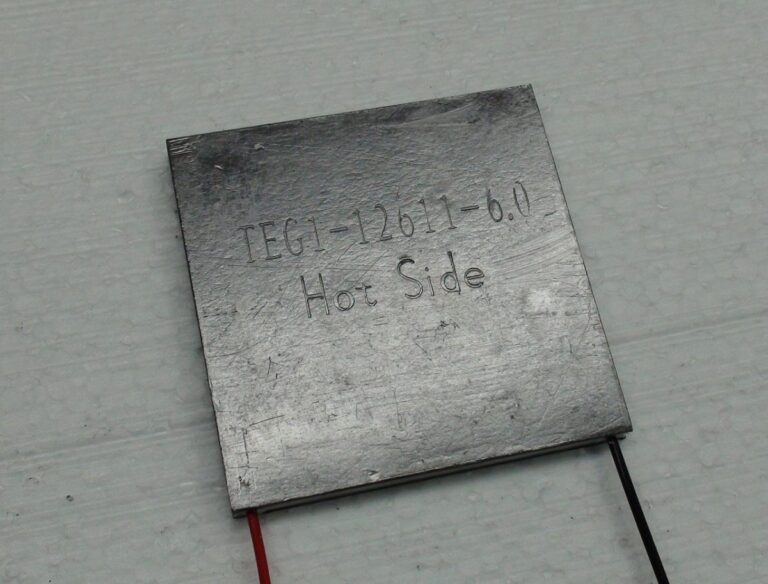

“Thermoelectric devices are solid-state devices that work according to the principle of the Seebeck effect for power generation and according to the Peltier effect for cooling,” the researchers explain. “Devices optimized for power generation are known as thermoelectric generators (TEGs) and for cooling are known as thermoelectric coolers (TECs).”

The Seebeck effect occurs when a temperature difference between two different semiconductors causes a voltage between the two substances. TECs are often used for industrial applications to convert excess heat into electricity. However, its high cost and limited performance have so far limited its wider application.

The experiment was conducted on a sunny August day between 11:15 AM and 1:35 PM in Shimla, the capital of the northern Indian state of Himachal Pradesh. Two polycrystalline silicon PV cells were used for the research: one with water cooling and TEC (PV cell 2) and one without cooling (PV cell 1). Both cells measured 60 mm x 60 mm x 3 mm.

Cell temperatures were measured over nine blocks via two Pt100 RTD temperature sensors attached to the back of the devices. In some cases the cells were shaded, and in some cases they were not. In other cases TEC was on or off and in other cases water cooling was active or not.

“The experiment clearly shows that the cooling of thermoelectric modules (TEM) is very effective and is able to maintain PV cell 2 at 25 C, while PV cell 1 operates at a maximum range of 55–63 C , leading to a temperature difference of 30–63 C. 38 C,” the scientist explained. “The experiment also shows that TEM itself contributes to at least a 10 degree temperature difference in addition to water cooling.”

After obtaining these results, the scientists used the PVSyst software to simulate energy losses due to elevated temperatures in 31 cities in Asia, Australia, Africa and North America. “The results show that average temperatures in the cities were between 27 and 57 degrees Celsius, leading to energy losses due to elevated temperatures of between 6 and 27%. This highlights the importance of further research and development of PV TECs for the energy improvement of commercial PV power plants,” she said.

In another part of the study, the academics took the measured results from cell 1 and compared them with the results of different temperature prediction models. Namely, they compared it with the nominal operational cell temperature model (NOCT); the NOCT model adapted by the National Energy Renewable Laboratory (NREL) USA; Faiman’s model; the Ross coefficient model; the Skoplaki model; and the Sandia Lab model.

“A comparison of six models for predicting PV cell temperatures with actual values shows that standard NOCT and Faiman models are accurate when wind speed effects are not significant,” the academics pointed out. “For conditions where wind speed is a dominant parameter, other models are likely to provide more accurate results. These results are important for future modeling of integrated PV-TECS systems for performance prediction in real outdoor conditions.”

Their findings were presented in the study “Modeling and experimental investigation of the cooling of field PV panels using thermoelectric devices for improved energy generation by industrial solar power plants,” published on Next energy.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.