As the industry becomes more comfortable with the way lithium batteries interact in confined spaces, engineers of large-scale energy storage systems are standardizing designs and packaging more batteries in containers. For every new 5 MWh lithium iron phosphate (LFP) energy storage container on the market, one thing is certain: a liquid cooling system will be used for temperature control. BESS manufacturers are ditching large, noisy and energy-hungry HVAC systems in favor of more reliable, refrigerant-based options.

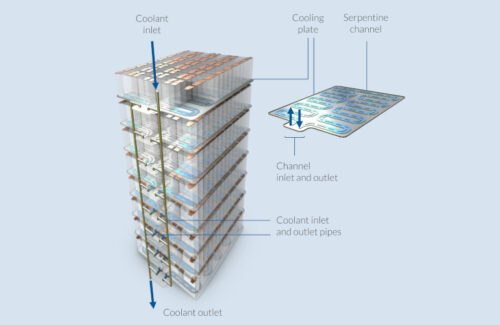

An illustration of a liquid cooling system by COMSOLa supplier of simulation software for product design.

Liquid cooling is probably the most recognized concept vehicles with flammable engines. A car’s engine burns fuel to create energy. Some of that energy propels the car forward and the rest is converted into heat. The engine must be kept cool so that coolant/antifreeze flows through pumps and hoses and works with the radiator to reduce the temperature. Liquid cooling systems in BESS work largely in the same way: coolant circulates around battery packs to manage heat.

Liquid cooling systems are carefully integrated into BESS containers to efficiently manage heat, says Zhehan Yi, director of utilities and ESS at CPS America. The liquid cooling system in the CPS Power Block 5 MWh container uses a multi-stage system control.

“It uses cooling lines and pumps that circulate the coolant through each battery module to regulate the temperature evenly,” he said. “There is a cooling unit in the electrical compartment that exchanges the heat and cools the coolant for circulation.”

Air cooling is still a common thermal management solution for BESS. It uses air to remove heat, usually with fans, heat sinks, air conditioning systems and other HVAC components. There’s nothing wrong with air cooling, but liquid cooling has more consistent benefits, Yi said.

“Liquid cooling has a higher cooling capacity and can regulate the temperature more evenly. It is less affected by the outside temperature,” he said. “It also reduces operating noise compared to air cooling.”

Liquid coolant is better at controlling temperature because the cooling lines are closer to each battery module. Air from fans can only reach a limited number of modules, and the temperature of that air depends on outdoor conditions. If you don’t rely on fans, sites won’t have constant hum – a welcome aural benefit for those who work and live nearby.

Canadian Solar’s e-STORAGE brand of 5 MWh containers using liquid cooling.

Fewer HVAC components also reduce additional electricity consumption. Although BESS stores energy for larger network and location needs, they do require electricity for maintenance. Closed-loop liquid cooling systems use less electricity than HVAC, making BESS more efficient.

In terms of maintenance, BESS liquid cooling systems require regular checks, just like a car’s system. The coolant level should be checked, along with the wear of moving parts such as pumps. Sensors in the system alert operators when a part or process fails, Yi said.

Perhaps the biggest benefit of using liquid cooling for temperature control in BESS is enabling more storage capacity in a smaller space. By removing the bulk of an HVAC system and better managing individual module temperatures, more battery racks can be placed in the containers. Liquid cooling is better at preventing escalation of thermal runaway – a major concern for system owners.

Many popular BESS brands have introduced 5 MWh models in recent years, thanks to liquid cooling. Hithium has graduated to the next level: a 6.25 MWh container with the same 20-foot footprint. This latest addition to the HiTHIUM ∞Block line is not yet available for the North American market (hopefully in Q2 2025), but is eligible for UL 9540A testing, which determines how systems operate in thermal runaway scenarios . The company’s 5 MWh models have successfully completed testing to receive certification, so expectations are the same for the larger version.

How big can BESS become? Research and development into lithium cell capacity is an ongoing effort, and their eventual home in containers will likely use liquid cooling to stay comfortable – until the next big idea in temperature control.