Researchers in Nigeria have proposed building inverted perovskite solar cells exclusively with completely inorganic transport materials and a lead-free perovksite absorber. Through a series of simulations, they showed that this device can achieve an efficiency of more than 30% with low production costs.

A research group in Nigeria has proposed building n-type heterojunction planar inverted perovskite solar cells without using transparent conductive oxides (TCOs) for the passivation contacts.

The researchers said this new design aims to maximize cell performance while reducing production costs and environmental impact. “The ability to achieve high efficiency using the reverse planar technique without using silicon composites and organic hole transport materials can lead to a wider variety of benefits in the sector,” she added.

TCOs are materials that exhibit both transparent and conductive properties and have been used for decades on both sides of the contacted crystalline silicon (c-Si) heterojunction. (SHJ) to provide solar cellse lateral guidance for collecting carriers. TCOs are is already widely used in the display industry, touchscreens and artificial and virtual reality applications.

Inverted perovskite cells have a device structure known as “pin”, where hole-selective contact p is at the bottom of the intrinsic perovskite layer i with electron transport layer n at the top. Conventional halide perovskite cells have the same structure, but in reverse: a ‘nip’ arrangement. With nip architecture, the solar cell is illuminated via the electron transport layer (ETL) side; in the pin structure, it is illuminated by the surface of the hole transport layer (HTL).

The Nigerian scientists used the SCAPS-1D solar cell capacity software, developed by Ghent University, to simulate the new cell configuration.

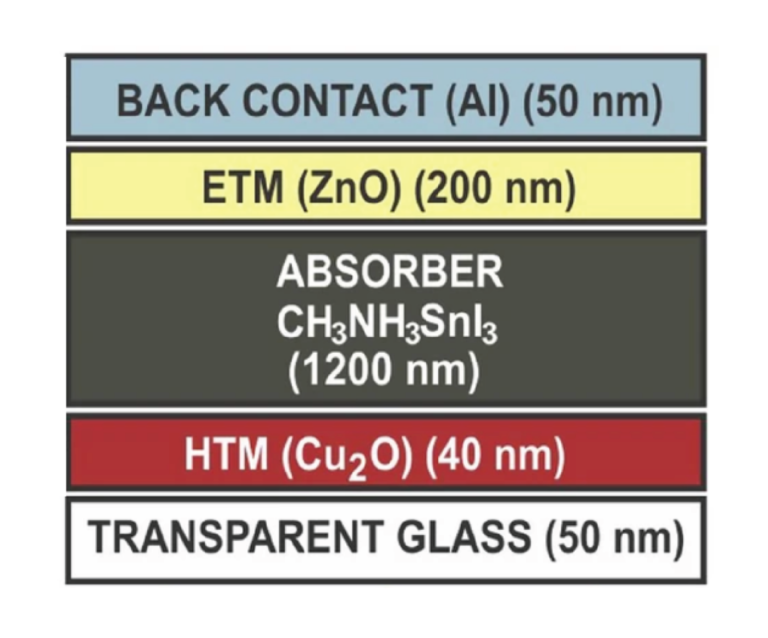

For the cell absorber, they considered using a lead-free perovskite material known as methylammonium tin triiodide (CH3NH3SnI3), which has an energy band gap of 1.3 eV. They also decided to use copper oxide (Cu2O) for the HTL and zinc oxide (ZnO) for the ETL. The cell design includes a glass substrate and an aluminum (Al) back contact.

“The choice for Cu2O since HTM in this work compared to other HTMs is based on the fact that it is relatively cheap compared to organics-based HTMs, high absorption coefficient, high intrinsic hole mobility and acceptable energy levels aligned with the absorber layer, high photochemical and thermal stability, as well as long-term stability in the air,” they explained. “ZnO is used as ETM due to its high absorption coefficient, higher electron mobility and aligned energy band gap with the chosen perovskite compared to the SnO2.”

Through the simulation, the group measured the thickness of both the HTM and ETM layers, as well as the doping concentration of the absorber. “The thickness of the HTM, absorber layer and ETM have been optimized to 40 nm, 1200 nm and 200 nm, respectively,” the report said.

Simulated under standard lighting conditions, the proposed device achieved an energy conversion efficiency of 30.17%, an open-circuit voltage of 1.0867 V, and a short-circuit current density of 33.4942 mA/cm2and a fill factor of 82.88%. “It is very clear that the photovoltaic performance of the proposed device is superior to that of other related studies reported in the literature,” the scientists said.

The group also confirmed that the proposed design paves the way for the production of simple, environmentally friendly, low-cost and highly efficient perovskite solar cells using completely inorganic transport materials.

The new cell concept was introduced in the study “Simulation and optimization of 30.17% high-performance N-type TCO-free inverted perovskite solar cell using inorganic transport materials,” published in scientific reports. The research team included academics from Nigeria’s University of Benin and the Federal University of Health Sciences.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.