The modules are equipped with Maxeon solar cells and a microprism plate that is said to maintain a transmission of more than 99%. The microprism array is printed on a PET sheet using the roll-to-roll embossing technique.

A group of researchers from Korean conglomerate Hyundai Motor Group and Kyung Hee University developed a new vertical solar panel concept for applications in existing outdoor structures or in urban areas where land availability is limited.

“This concept is a technology that increases the amount of incoming sunlight without internal changes to the solar cell,” said the study’s lead author, Byunghong Lee. pv magazine. “The biggest advantage of this technology is that it is inexpensive, as it can be applied to commercialized polyethylene terephthalate (PET) films.

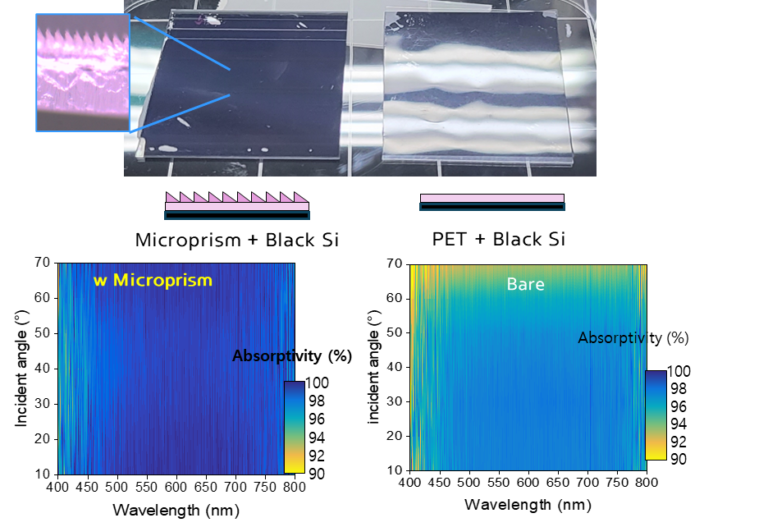

The panels are equipped with polyethylene terephthalate (PET) sheets with microprisms that are said to reduce reflection losses while maintaining greater than 99% transmittance. The microprism array is printed on a PET sheet using the roll-to-roll embossing technique.

“This method enables the scalability of microprism slabs to larger sizes, even up to meters, while maintaining the precise replication of the microprism morphology,” the scientists explained, adding that the slab was then attached to the module via an adhesive index-matching gel. .

The group built an experimental module using solar cells from Singapore-based manufacturer Maxeon and simulated its performance under real-world conditions in Uiwang, South Korea. The device was exposed to direct sunlight, which follows a straight path from the sun to the cells, and scattered sunlight, which is scattered by atmospheric particles and clouds.

The analysis showed that the module can achieve higher levels of power generation compared to conventional vertically mounted modules, which is attributed to the omnidirectional anti-reflection properties of the microprism plate.

“The measured results revealed a consistent trend of improved power generation with the microprism plate over the extended testing period,” the academics said. “The developed microprism sheet is promising for maintaining flawless PV performance against the influence of weather-related factors. During the test period we did not observe any degradation due to pollution.”

According to the research team, the microprism sheet has a reflectivity of less than 0.01, demonstrating that it has better omnidirectional anti-reflective properties compared to traditional single-layer and multi-layer anti-reflective coatings. “Indoor and outdoor tests have confirmed that the microprism plate can contribute to the year-round energy harvesting of upright SPs at any installation location,” the report concluded.

The new concept was introduced in the newspaper “High-efficiency upright solar panels with anti-reflective microprism printed plates,” published in Cell Reports – Physical Sciences. “To further validate the impact, long-term outdoor testing at different locations at different latitudes is required,” the scientists said, pointing to future work they plan to undertake to improve the proposed technology.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.