Researchers from Japan’s Riken Center for Emergent Matter Science have fabricated an organic solar cell that has achieved waterproofness without reducing flexibility. At 3 micrometers thick, it is believed to be the first cell of its kind to survive a washing machine cycle and maintain its efficiency after multiple cycles.

Researchers from the Riken Center for Emergent Matter Science in Japan have manufactured a waterproof and flexible organic photovoltaic (OPV) solar cell that can be used in portable electronics.

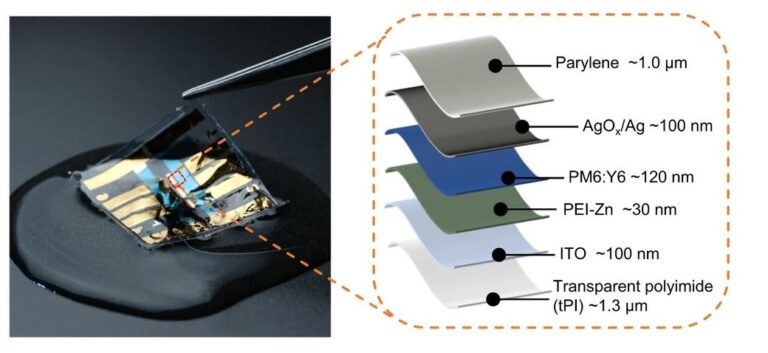

The team’s cell consists of an in-situ growth of a hole-transporting layer to strengthen the bond between the active layer and the anode. The anode layer, in this case a silver electrode, was deposited directly on the active layers and then subjected to a thermal annealing process, during which the film was exposed to air at 85 degrees Celsius for 24 hours. This created better interlayer adhesion than typically found with photovoltaic films, improving waterproofing. Sixing Xiong, the first author of the paper, said that this method allowed the team to create a film that was three micrometers thick.

The researchers recorded a champion efficiency of 14.3% under one sun exposure for their cell, which according to their research paper “outperforms existing waterproof organic solar photovoltaics.”

The team then tested their cell by completely submerging it in water for four hours and found that it still performed 89% of its original performance. When the film was stretched by 30% underwater 300 times, it retained 96% of its performance. The cell was then put through a washing machine cycle and survived, which has never been reported before for such a thin encapsulation layer, according to the research report.

“The efficiency degradation was limited to just 10% even after the devices were subjected to two washing cycles in a washing machine, each lasting 66 minutes,” the scientists said. “These organic solar materials offer remarkable stretchability and waterproof properties, even with such a thin structure, making them well suited for wearable electronics.”

Kenjiro Fukuda, one of the paper’s corresponding authors, said the team has developed a method that can be used more generally. “Looking to the future, by improving the stability of devices in other areas, such as exposure to air, strong light and mechanical stress, we plan to further develop our ultra-thin organic solar cells so that they can be used for truly practical wearable devices ,” he said.

The full findings are available in the study “Waterproof and ultra-flexible organic solar photovoltaic with improved interface adhesion”, published in Nnature Communication.

In 2022, another research group at Riken developed heat-shrinkable polymers that can be used to laminate organic photovoltaic devices to curved surfaces.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.