Solertix claims to have reduced yield losses when scaling up from cells to modules by using ultra-narrow 19.5 μm interconnects. It also says that the proposed interconnection technique can be used to achieve 30% efficiency in 4T tandem designs with customized area, with a perovskite module over a silicon cell.

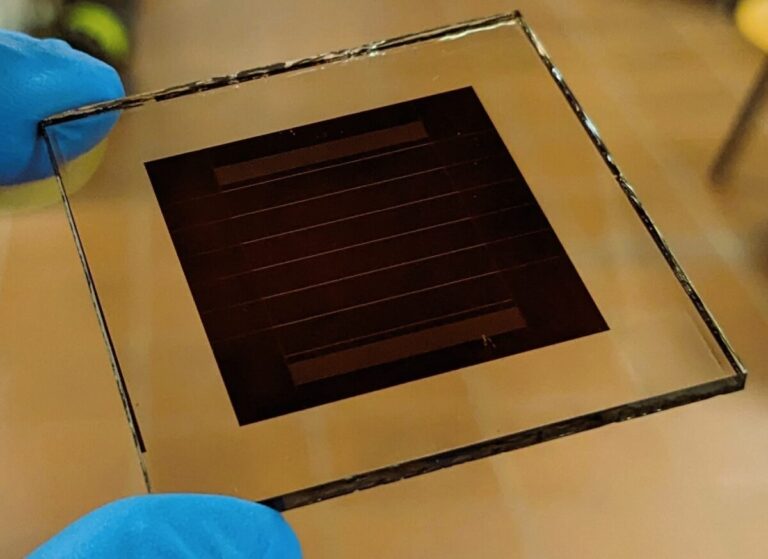

Italian perovskite specialist Solertix, part of Italy-based solar manufacturer FuturaSun, has manufactured mini perovskite solar panels with an active area of 2.6 cm2 and an energy conversion efficiency of 20.7%.

“We have optimized the laser processes to manufacture the compounds used to go from cells to modules,” said Francesco Di Giacomo, CTO of Solertix. pv magazine. “Since the area used for the interconnections does not produce energy, we have introduced a new layout to minimize this area without introducing other types of losses. The factor that takes this into account is the geometric fill factor (GFF), which describes the ratio between active area and the sum of active area and interconnections. We achieved a record of about 99.6%, while in the literature it is difficult to go beyond 95%.”

In the research paper “More than 99.5% geometric fill factor in perovskite solar mini-modules with advanced laser structuring”, written in collaboration with scientists from the University of Rome Tor Vergata, of which Solertix is a spin-off, the Italian startup explained that when scaling up perovskite cells to modules, losses can be caused by loss of inhomogeneity of the layers, P2- ohmic loss, shunts across P1 and P3, and sheet resistance loss.

The so-called P1, P2 and P3 writers correspond to the three write steps of the process for building the monolithic connections that add voltages between cells in modules. The P1 and P3 steps focus on isolating the back contact layers of adjacent cells and the P2 step creates an electrical path between the back contact of a cell with the front contact of an adjacent cell. The P3 step in particular is often a source of undesirable effects, such as back contact delamination, flaking or poor electrical insulation, due to residues left in the trench.

The module is built with three cells, each with an area of 0.87 cm2. The cells are all designed with a substrate made of glass and indium tin oxide, a hole transporting material based on poly(triarylamine) (PTAA), a perovskite absorber, an electron transport layer based on phenyl-C61-butyric acid methyl ester (PCBM), a bathocuproin (BCP) buffer layer and copper (Cu) metal contact.

“Two rectangular shapes with an active area of 1 cm2 have been designed, with the aim of reducing resistance losses that mainly occur with the TCO electrode: the active areas are defined by a P3 scratch, followed by a P2 scratch to remove the remaining metal electrode as a current collection electrode for the TCO,” the researchers said, noting that the use of the P2-P3 process allowed the integration of a current collection grid with the same metal layer as the top electrodes.

The group tested a module built with this architecture and an ultra-narrow 19.5 μm interconnect under standard lighting conditions and found that it can achieve an efficiency of 20.7%, a fill factor of 81.7% and a geometric fill factor of 96% , without relevant resistance losses are detected.

Looking ahead, the team said it plans to employ an unspecified advanced alignment procedure to prevent possible warping of the module during processing. “By applying this new approach to the semi-transparent modules created in Solertix, we are close to achieving 30% efficiency using a surface-tuned 4T tandem with a perovskite module over a silicon cell,” Di Giacomo said, without giving further details.

Solartix was acquired by FuturaSun in June 2023. It was founded at the Organic Solar Center (CHOSE), founded by Professor Aldo Di Carlo, who also took on the position of chairman of the scientific committee of the Italian startup.

In March 2021, the University of Rome Tor Vergata presented a perovskite solar panel with a total active area of 42.8 cm2 and an opening area of 50 cm2. The panel was built with 20% efficient perovskite cells connected in 14 series and was able to maintain 90% of initial efficiency after 800 hours of thermal load at 85 degrees Celsius.

A few months later, it unveiled a perovskite solar panel with cells based on it cesium methylammonium formamidinium with three cations (CsMAFA).

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.