An international research team has developed a performance-enhancing treatment for perovskite solar cells based on phenethylammonium chloride (PEACl), which is also claimed to reduce the number of process steps. Using this technique, the group built a champion device with an efficiency of 20.9%.

An international research team has developed a method to fabricate perovskite thin films using a precursor known as phenethylammonium chloride (PEACl) in a simultaneous deposition and passivation step.

“Such a simplified process could allow researchers to create cells with more consistent quality,” Tim Kodalle, the scientist who led experiments completed at Lawrence Berkeley National Laboratory (Berkeley Lab), told me. pv magazine. “In the longer term, the process could potentially reduce the costs and energy consumption of perovskite cell production.”

The proposed method is said to reduce the number of synthesis steps while stabilizing the halide-perovskite film for more than a month. The team said it used a simplified approach, combining a modified 2D/3D fabrication process with the incorporation of large halides into the 2D/3D perovskite films. The integrated deposition and passivation strategy used PEACl dissolved in isopropyl alcohol (IPA).

The PEACl:IPA solution was deposited as the modified antisolvent (AS) during the 3D halide-perovskite thin film process, where passivation via 2D perovskite was integrated into the deposition step of the 3D perovskite films. The PEACl was added to the antisolvent during the spin coating step. The mixed 2D/3D film was then annealed on a hotplate.

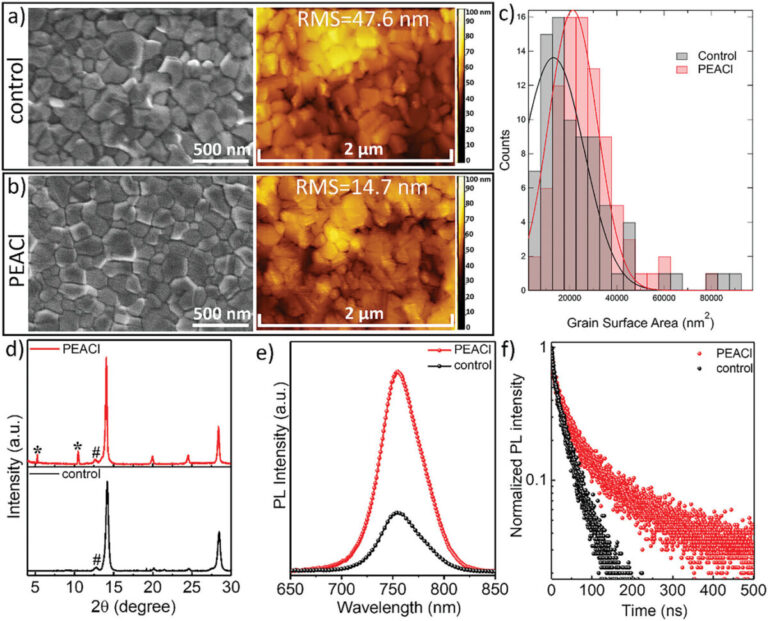

The team compared the performance of the PEACI:IPA-based solar cell with that of a reference device without the PEACI treatment.

“The PEACl-PSCs demonstrate significantly improved device performance and reproducibility compared to the control cell,” the report said, noting that the performance of the champion cell was verified with a series of tests with results indicating that it had a high stabilized had efficiency.

This cell achieved an energy conversion efficiency of 20.9%, an open-circuit voltage of 1.13 V, a short-circuit current density of 23.0 mA/cm2 and a fill factor of 80.0%. The benchmark cell achieved an efficiency of 19.0%, an open-circuit voltage of 1.10 V, a short-circuit current density of 23.2 mA/cm2 and a fill factor of 73.2%.

Image: Thor Swift/Berkeley Lab

The team attributed the performance improvement to the reduction in the non-radiative recombination rate and the improvement of the perovskite-hole transport layer interface.

To further investigate how the PEACl approach affected performance, since it was unclear how the incorporation of the bulky molecules into the preannealed wet film affects the nucleation and subsequent crystallization of the perovskite film, a team at Berkeley Lab was asked to conduct a to conduct a large number of studies. on-site measurements.

Various in situ measurement techniques were used. At the Advanced Light Source, photoluminescence (PL) and grazing incident wide-angle X-ray scattering (GIWAXS) data were collected using a custom analytical chamber. In addition, the team used ultraviolet-visible spectroscopy to observe the evolution of the films’ absorption as they formed to capture differences in the optical properties of the samples, according to Tim Kodalle, the scientist who led the experiments conducted at Berkeley Lab were completed.

The researchers then correlated the data streams from the three techniques to analyze the temporal evolution of the crystalline structure of the samples. The team discovered that PEACl slows down the crystal growth process, leading to a larger average grain size and a narrower grain size distribution. This in turn reduces carrier recombination at grain boundaries and improves device performance and stability.

“The data suggest that during annealing of the wet film, the PEACl diffuses to the surface of the film and forms hydrophobic (quasi-) 2D structures that protect most of the perovskite film from moisture-induced degradation,” the researchers said. that the two-step PEACl process can create a thin protective barrier that keeps moisture out.

The details of the study appear in “An integrated deposition and passivation strategy for controlled 2D crystallizationpublished by Advanced materials. Researchers from the University of Stuttgart, Lawrence Berkeley National Laboratory, Forschungszentrum Jülich, Brandenburg University of Technology, McGill University and Zentrum für Sonnenenergie und Wasserstoff Forschung collaborated on the project.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.