The new conductive adhesive ink, invented by researchers from Iran, is made of polymethyl methacrylate (PMMA) and is used as an intermediate layer between the hole transport layer of the cell and carbon foil. It reportedly ensures higher cell stability while offering remarkable efficiency.

A group of scientists led by Sharif University of Technology in Iran have developed a new conductive adhesive ink that can be used as an interfacial bonding layer in perovskite solar cells.

“The adhesive ink aims to improve cell stability and efficiency,” said the study’s corresponding author Nima Taghavinia. pv magazine. “We have developed a cheap and simple process that is compatible with large-area applications.”

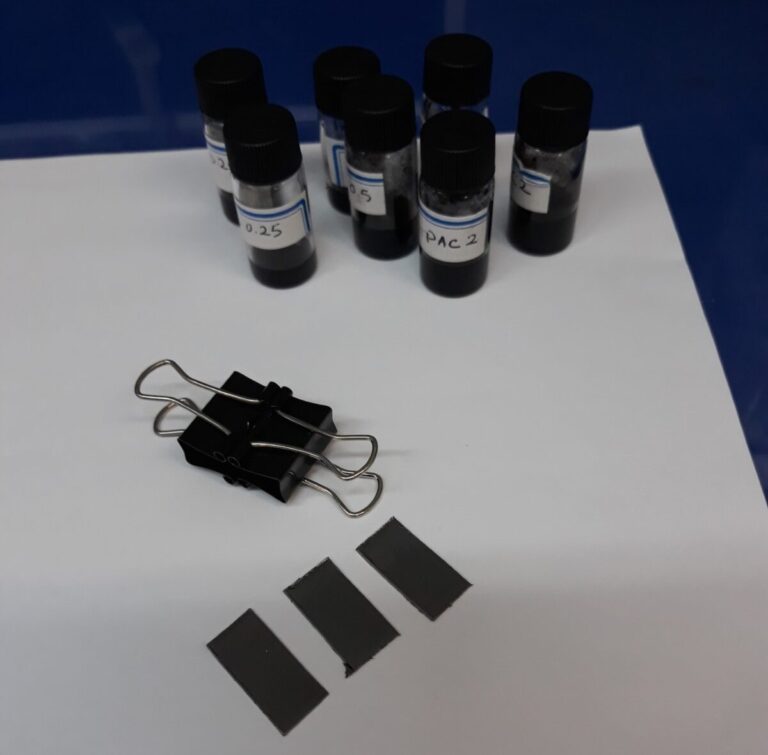

The adhesive is made of polymethyl methacrylate (PMMA), a commonly used polymer as a replacement for glass in various industries based on its low cost, excellent mechanical, electrical and optical properties, thermal and environmental stability, low weight and high light transparency. It is used as a boundary layer between the hole transport layer (HTL) of the cell, made of copper indium sulfide (CuInS2) nanoparticles and a top carbon film that relies on highly conductive carbon black (HCCB).

The adhesive was embedded in a cell consisting of a substrate made of fluorine-doped tin oxide (FTO), an electron transport layer (ETL) based on carbon-titanium dioxide (c/TiO2), a mesoporous TiO2 layer, the perovskite absorber, the HTL based on CuInS2 and the top carbon film with HCCB.

The researchers noted that without the new glue, this cell configuration tended to be unstable, as the carbon electrodes often came loose after taking measurements.

“The conductive adhesive ink was drop-cast onto the carbon film with an area of 0.27 cm2,” the researchers said, referring to the adhesive deposition process. “The carbon foil was then transferred to the as-prepared FTO stack of glass/c-TiO2/mp-TiO2/perovskite/CuInS2 in a manner that the adhesive ink contacts the HTL.”

Through a series of tests, the research group discovered that PMMA is the key to achieving stable and reliable adhesion of carbon film to the cell. It also explained that adding the CuInS2 nanoparticles to the ink makes the adhesive consistent with the underlying HTL, with the CuInS2 nanoparticles contributing to the hole transfer mechanism.

“Our results showed that adding 2 wt% HCCB nanoparticles to the PMMA/CIS mixture at a ratio of 1:3 leads to the maximum conductivity for the achieved adhesive layer, resulting in the maximum efficiency of 17.2 %, which is comparable to that of gold-based counterpart cells (18.2%),” the academics said. “In addition, using the proposed carbon-laminated electrode, we achieved a long-term stability of approximately 92% after 54 days of storage, which is an improvement of approximately 17% compared to the stability of gold-based counterparts.”

Their findings are available in the study “A conductive adhesive ink for carbon-laminated perovskite solar cells with improved stability and high efficiency,” published in Solar energy.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.