In his second monthly column for pv magazinethe IEC is highlighting research into flexible crystalline silicon solar cells led by researcher Zhengxin Liu, the vice chairman of IEC Technical Committee 82, which sets standards for solar PV energy systems.

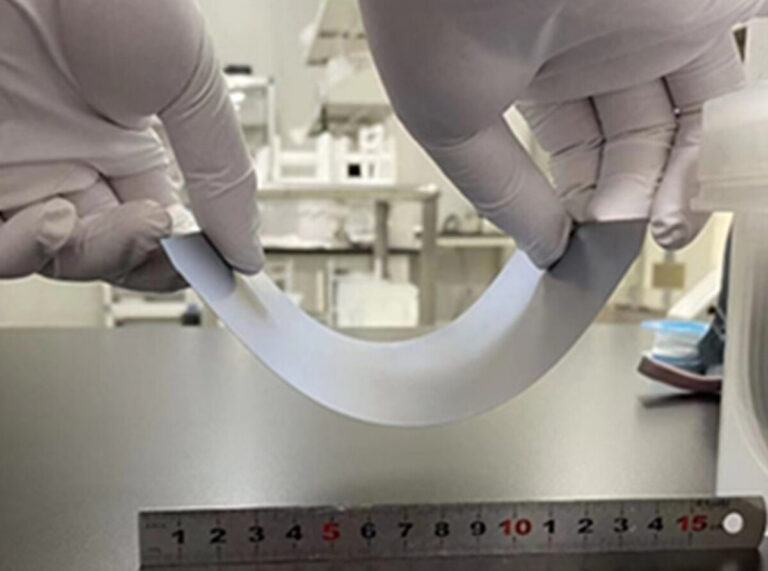

Although crystalline silicon solar cells possess many advantages, including their material richness, high energy conversion efficiency and operational stability, as well as their mature manufacturing process, it has always been taken for granted that they cannot be used in flexible applications due to the brittle characteristics of crystalline silicon wafers (Fig. 1). For this reason, silicon electronic devices are usually encapsulated by hard glass and/or backplates to form traditional monofacial or bifacial photovoltaic modules. These modules account for more than 95% of the current photovoltaic market.

The road to foldable silicon wafers

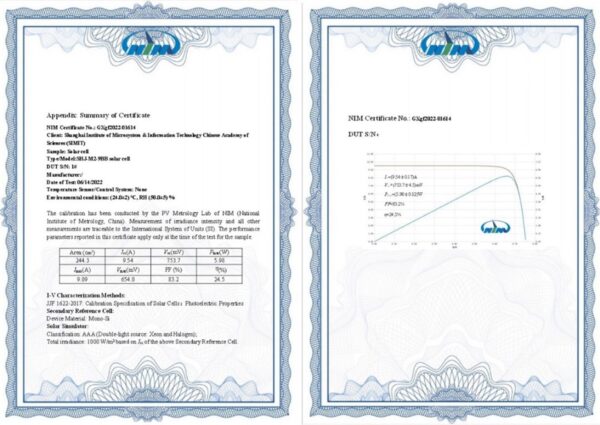

However, their low power-to-mass ratio hinders their installation on satellites, buildings, cars, clothing, and other curved surfaces. My research team developed a strategy to fabricate foldable silicon wafers with a small bend radius of approximately 4 mm. When made into lightweight flexible amorphous crystalline silicon heterojunction solar cells, the energy conversion efficiency is independently calibrated to more than 24% (Fig. 2). When the cells are encapsulated in a large flexible solar module (>10,000 cm2), the energy conversion efficiency reached 22.8%, much higher than other flexible counterparts made from cost-effective materials.

Compared to standard bifacial modules encapsulated by glass, the weight-to-power ratio of flexible bifacial modules in this study decreases by approximately 95%, potentially paving the way for a large self-powered electronics market in the near future.

Image: IEC

Image: IEC

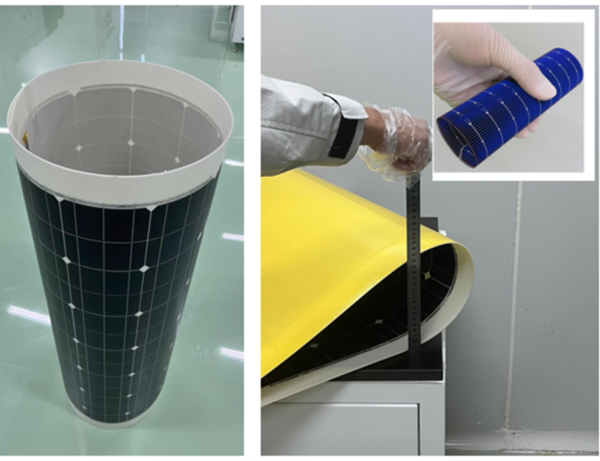

Long-term stability is a problem

For flexible applications, special attention must be paid to long-term stability. For example, microcracks are caused during the encapsulation of modules. More detailed research shows that these microcracks are located at the end points of solder strips (at the edges of the device). This suggests that maximum compressive stress is applied when the endpoint of the solder strips and the surface of the device come into contact. This is confirmed by a finite element analysis using the COMSOL Multiphysics software. Our research team proposed to blunt the pyramids at the edges of the wafer and convert the sharp V-shaped channels into rounded U-shaped channels between the surface pyramids. By spreading the voltage, this strategy reduced the maximum voltage by about one order of magnitude, making the solar cells more resistant to wafer distortion and frequent vibration. The bending radius of an M2 size cell (156×156 mm) is less than 8 mm. When encapsulated in large modules of more than 2 m2, they can be rolled in the same way as thin-film modules made of a-Si, organics, CIGS, CdTe and perovskite (Fig. 3). The least critical bend radius is less than 5 cm, indicating that they are suitable for many niche applications. Furthermore, these flexible solar cells are free-standing devices, unlike other thin-film cells deposited on expensive organic substrates or stainless steel.

The research group has demonstrated applications for high-altitude vehicles between 10-100 km altitude. In this range, the space radiation of ultraviolet radiation and high-energy particles is not very challenging. More experiments need to be conducted to estimate the impact of more extreme tasks before deploying them in the future.

Image: IEC

Standards and testing are required

In this study, the research team also notes that no detailed testing standards exist for flexible silicon photovoltaic modules. IEC Technical Committee 82, which sets standards for solar PV energy systems, could lead the work in this area. An experimental configuration for vibration testing has yet to be determined. The parameters for bending tests include bending radius and retention time, and other testing methods may include electroluminescence, photoluminescence, current-voltage analysis and so on. Finally, tension effect tests are recommended because the applied tensile force can result in failure of the encapsulant and destroy the conformal contacts between the encapsulant and the cell surface, as well as the conformal contacts between the solder strips and the cell surface.

Zhengxin Liu is an expert in solar cell materials and devices and solar cell measurement technology. His current research interests include high-efficiency crystalline silicon solar cells, the physics of heterojunction structures, and the standardization of solar cells. He presents a summary of his research team’s groundbreaking paper on flexible crystalline silicon solar cells, which was initially published in the journal nature.

The International Electrotechnical Commission (IEC) is a global non-profit membership organization that unites 174 countries and coordinates the work of 30,000 experts worldwide. International IEC standards and conformity assessment are the basis of international trade in electrical and electronic goods. They facilitate access to electricity and verify the safety, performance and interoperability of electrical and electronic devices and systems, including, for example, consumer equipment such as mobile phones or refrigerators, office and medical equipment, information technology, electricity generation and much more.

The views and opinions expressed in this article are those of the author and do not necessarily reflect those of the author pv magazine.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.