British scientists have designed a new heat pump concept that they claim could be particularly beneficial for newly developed areas or potential residential complexes. The system uses ice or ice slurry as a heat source and its energy consumption is reportedly lower than that of several types of commercially available heat pumps.

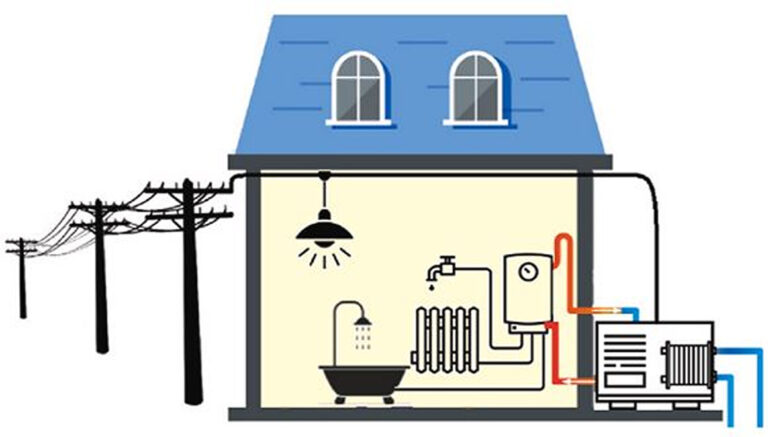

A research group at the University of Nottingham in the United Kingdom has developed a heat pump system that uses water or ice as a heat source and uses existing gas pipes for energy transfer.

The researchers explained that heat pump systems with an ice source generate heat from ice or ice slurry sourced from water supplied via underground gas pipelines or stored water supplied by seasonal rainfall. “This process takes advantage of the high enthalpy of phase change, allowing significant energy absorption with minimal mass or volume,” she added. “This heat pump concept is effective with water as a heat source due to the high latent heat of fusion of water, which allows substantial energy absorption with a low mass.”

The proposed system, like geothermal heat pumps, can be connected to a central heat pump system, where several residential units are connected to each other. This configuration is said to be particularly beneficial for newly developed areas or potential residential complexes, “where dimensions and pipeline layouts for new units can be meticulously planned.”

The system uses a compression refrigeration cycle that moves hot compressed gas from the compressor to the condenser, which then releases heat to the heat sink, where it undergoes a phase change and turns into a liquid, resulting in a temperature drop. The liquid refrigerant then enters the evaporator, where it absorbs the heat from the cold source and evaporates. In the next stage, the vaporized refrigerant returns to the compressor, where it is recompressed to restart the cycle.

The academics acknowledged that the proposed heat pump has a lower coefficient of performance (COP) compared to conventional heat pumps, but also emphasized that these systems have reduced water circulation, resulting in lower additional costs due to the higher energy consumption and pipeline construction.

They also explained that the proposed solution is ideal for rainy countries such as the United Kingdom, which is equipped to use wastewater from ice production in city sewers without significant consequences.

“Importantly, the water used by the ice source heat pump in this scenario undergoes a closed cycle: part of the wastewater is treated and injected into the city gas pipes, absorbing heat from both the wastewater and the ground within sewer walls and gas pipes. ,” they further explained. “In this arrangement, the heat pump discharges cold water or ice sludge into the city sewer, which, after simple treatment, is partly returned to water storage tanks for reuse in the process and further driving the heat pumps.”

Through a series of simulations, the researchers assessed the performance of the ice source system and compared it to that of air and water source heat pumps, with a more specific focus on a comparison with a 10 kW commercial air source heat pump from Germany. manufacturer Vaillant.

Their analysis showed that the ice source system has a factor of 2.7 higher energy consumption compared to conventional gas boilers, with electric resistance heating, air source systems and water source systems having values of 7.5, 3.2, 2.5. and 2.7 respectively.

“In addition, electricity consumption exceeds the current peak for 89%, 47%, 35% and 39% of the hours in the year for each respective system,” they pointed out. “These findings highlight the role of the proposed system in managing peak electricity demand and improving generation and transmission capacity following the phase-out of natural gas.”

The system was introduced in the newspaper “Ice source heat pump system for gas pipe energy supply – Part 1: Performance analysis in residential units”, which was recently published in Energy.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.