Researchers in China have discovered that a special type of hygroscopic hydrogel, made from polyacrylamide polymer and lithium chloride, can reduce the temperature of PV panels by up to 7.5%. They also developed a mathematical model to analyze the operational mechanisms and factors responsible for cooling performance.

Scientists at South China University of Technology have developed a passive cooling technology for solar modules that uses a Hygroscopic hydrogel as a coolant. Hygroscopic hydrogels are a new type of absorbent materials that offer extreme water absorption, efficient water collection and release kinetics, and low desorption enthalpies.

In the study “Hygroscopic hydrogel-based cooling system for photovoltaic panels: an experimental and numerical study”, published in Applied thermal technologythe research team said that this is not the first attempt to hygroscopic hydrogels to reduce the temperatures of PV modules and the novelty of their approach consisted in assessing the impact of the improved thermal conductivity on heat and mass transfer during the evaporative cooling process of the hydrogel.

“We developed a mathematical model to simulate heat and mass transfer processes in real environments,” says the corresponding author of the study. Li-Zhi Zhang, narrated pv magazine. “We analyzed the operational mechanisms and factors responsible for controlling the system from the perspective of heat and mass transfer resistance.”

In particular, the group investigated a hygroscopic hydrogel composed of the polyacrylamide (PAM) polymer and lithium chloride, a moisture absorbent that can absorb and release moisture depending on its sorption properties, ambient temperature and humidity. The hydrogel is heated by the panel during the day, while at night it absorbs water from the air to regenerate itself via an evaporation-sorption cycle.

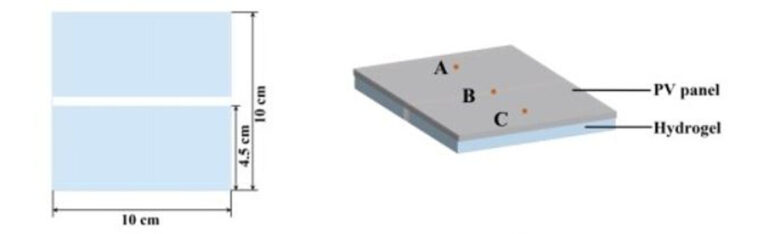

The researchers placed the hydrogel with a thickness of 6 mm on the back of solar panels measuring 10 cm x 10 cm that were installed at a tilt angle of 30 degrees. They then ran a series of simulations over 96 hours to compare the cooling and electrical performance parameters of the panels with those of reference panels without cooling.

Their analysis showed that the hydrogel can significantly reduce the temperature of the PV modules between 8:00 PM and 4:30 PM and up to 7.5 C in the afternoon. Furthermore, the hydrogel was responsible for increasing the power output of the cooled system by up to 2.1% compared to the uncooled system.

“The hydrogel then began to absorb moisture from the air, after which the temperature of the PV panel in the cooled system exceeded that of the single PV panel, due to the heat released during sorption,” the scientists explained. “The combined effects of decreasing light intensity and decreasing water content of the hydrogel negatively affected the cooling performance of the cooled system.”

The simulation also showed that the external heat transfer resistance, internal mass transfer resistance, and water content of the hydrogel were the key factors determining the overall system performance.

“Increasing the thermal conductivity of the hydrogel could improve system performance by reducing internal thermal resistance,” the academics pointed out. “Once the thermal conductivity reaches 1 W/m/K, the internal thermal resistance becomes negligible compared to the external thermal resistance, and the thermal conductivity further increases, which has a decreasing effect on system performance.”

Looking ahead, the group plans to assess the technical and financial feasibility of the technology.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.